Embracing Innovative Technology for a Secure Future

FABRICS MANUFACTURER

-

0+

0+Enterprise establishment

-

0+

0+Employees

-

2026-01-30High Visibility Flame Retardant Fabric: Is It the Ultimate Safety Solution for Hazardous Workplaces?High visibility flame retardant fabric is widely used in industrial safety clothing, protective uniforms, and emergency response gear. By combining fi...

-

2026-01-23We are pleased to announce that our General Manager, Mr. An Biao, participated as a Council Member in the 2nd Session of the 5th Council of the China ...

-

2026-01-22When working in environments with potential fire hazards or low visibility, safety is paramount. One of the key ways to stay safe is by wearing the ri...

-

2026-01-19Our General Manager, An Biao, is representing the company at the 2025 Annual Meeting of the Haian City Industrial Economic Federation today.

In the field of protective materials, achieving the pinnacle of a single performance characteristic often comes with compromises in other areas. Aramid blended fabrics overcome this limitation through precise material ratios and innovative processing, cleverly integrating the unique advantages of different fibers to create a new composite material that combines multiple protective properties with practical value. This fabric not only maintains the inherent high strength and high-temperature resistance of aramid fibers, but also, through scientific blending, imbues the material with new vitality and broader application possibilities.

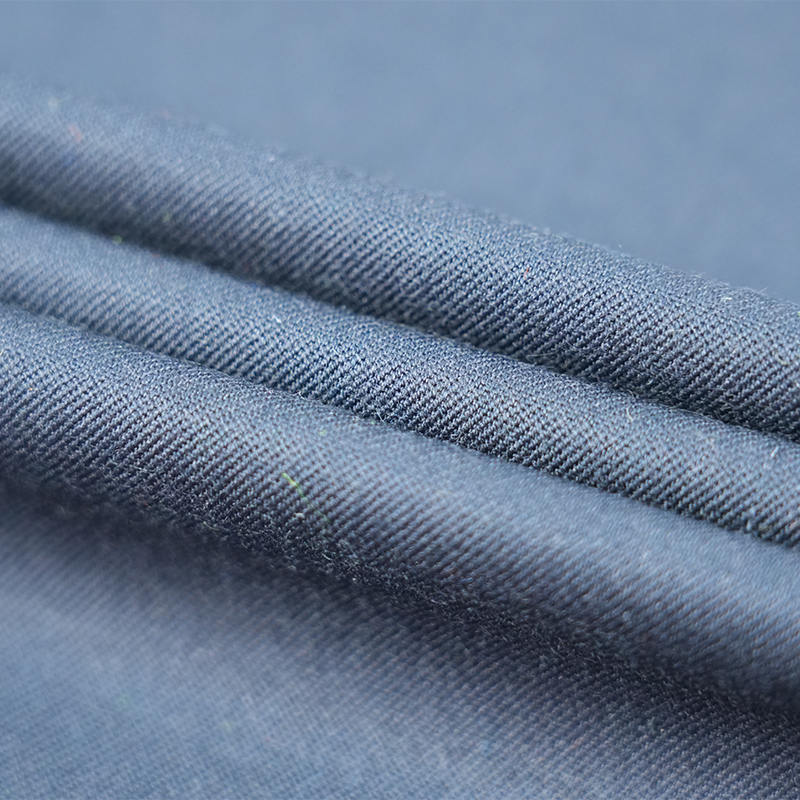

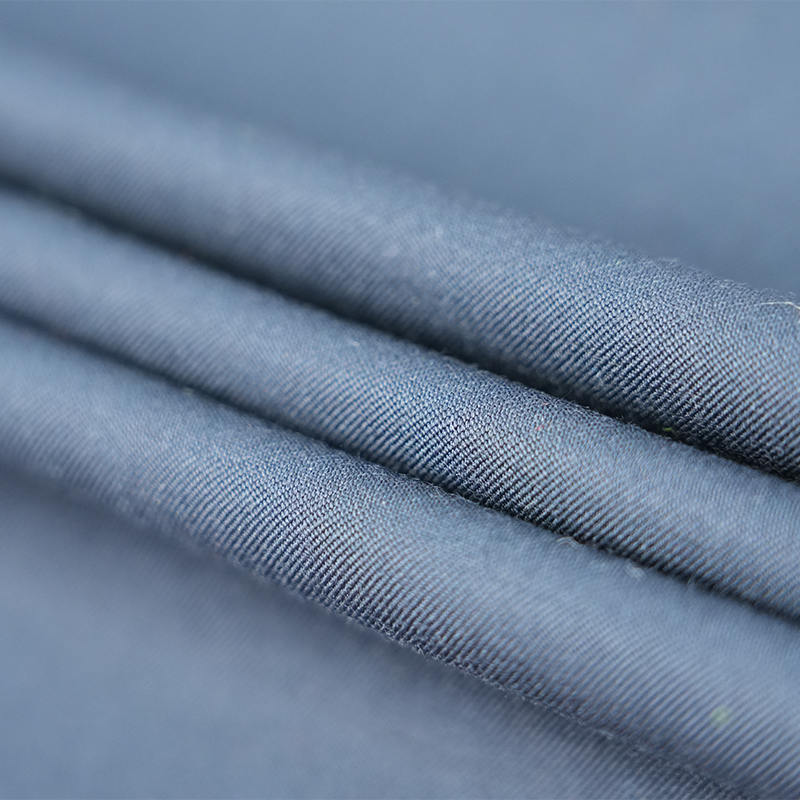

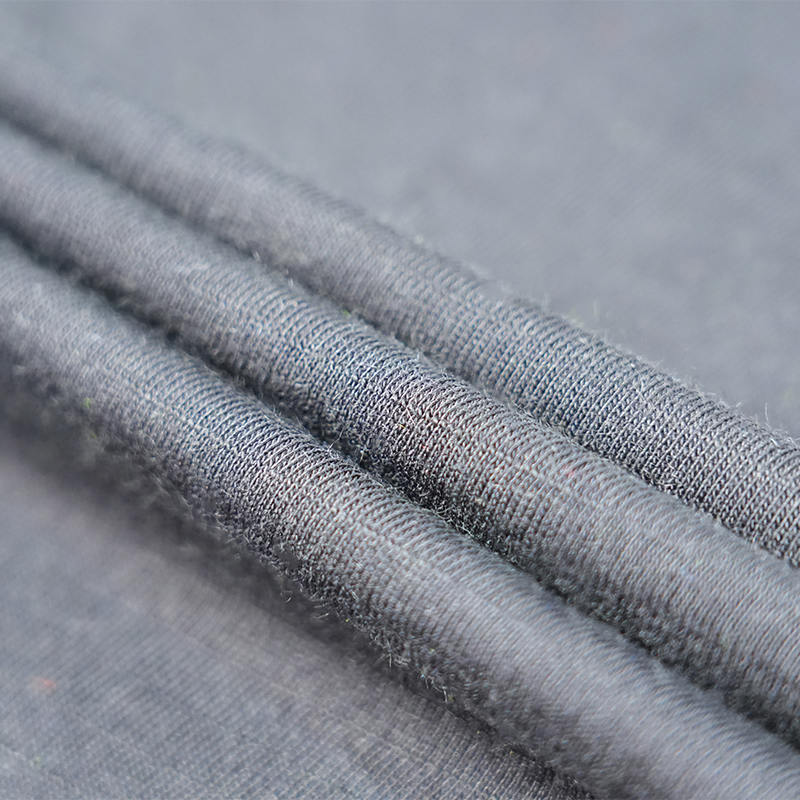

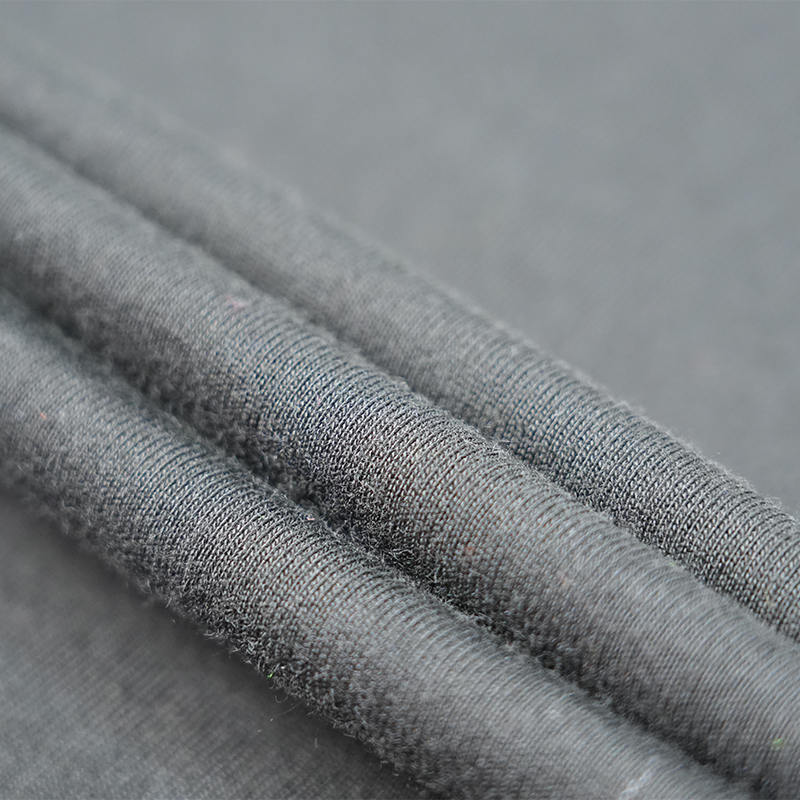

The essence of aramid blended fabrics lies in their adaptable, adaptable nature. By combining aramid with fibers such as cotton, polyester, and Modal in varying proportions, and employing specialized spinning processes, the fabrics can be precisely tailored to the needs of various applications. For example, blending aramid with flame-retardant viscose creates a softer feel, significantly improving the stiff feel of traditional aramid products. Combining aramid with moisture-wicking fibers like Coolmax significantly enhances wearing comfort in hot environments. More notably, the "core-sheath structure" spinning technology allows for functional compartmentalization within a single yarn—aramid acts as the core to provide strength, while other functional fibers serve as the sheath to improve surface properties, creating a fabric with complex functions at the microscopic level.

The application value of this material is evident in numerous professional fields. Firefighting uniforms blended with aramid and phase change materials not only maintain flame retardancy but also absorb excess body heat in high-temperature environments. Oil platform workwear, blended with aramid and conductive fibers, meets both flame retardancy and anti-static requirements. Aramid blended fabrics are also thriving in the civilian sector: high-end motorcycle jerseys utilize their tear resistance and breathability to provide all-weather protection for riders. Outdoor workwear, thanks to its weather resistance and comfort, has become a top choice for construction and forestry professionals. Advances in manufacturing technology have even led to the development of smart wearables. By combining aramid with materials like conductive silver fibers, smart clothing with both protective and physiological monitoring capabilities has been developed. 3H.Safety.Technology, a manufacturer of flame-retardant functional fabrics under the brand "3H.Safeloya®," is dedicated to product research and development and fabric production. As a professional flame-retardant fabric manufacturer and workwear manufacturer, its products are widely used in various industries, including petroleum, petrochemicals, chemicals, gas stations, power generation, coal mining, steel, metallurgy, and machining. The company maintains strict quality management and implements full product lifecycle traceability in accordance with national regulations. Our products are of high quality, environmentally friendly, and hygienic, ensuring peace of mind for our customers and users.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى