With national standard GB8965.1-2020 B grade GB12014 certificate. Permanent flame retardant, anti-static, and high temperature resistant. No shrinkage and melting phenomenon when fire self-extinguishing, can effectively prevent the spread of flames, for harsh environments and high-temperature working conditions can provide comprehensive and permanent professional protection!

Petrochemical fabrics are comfortable and lightweight, the advantages of a high-temperature working environment are especially obvious, high breathability, wear resistance, permanent flame retardant, and anti-static.

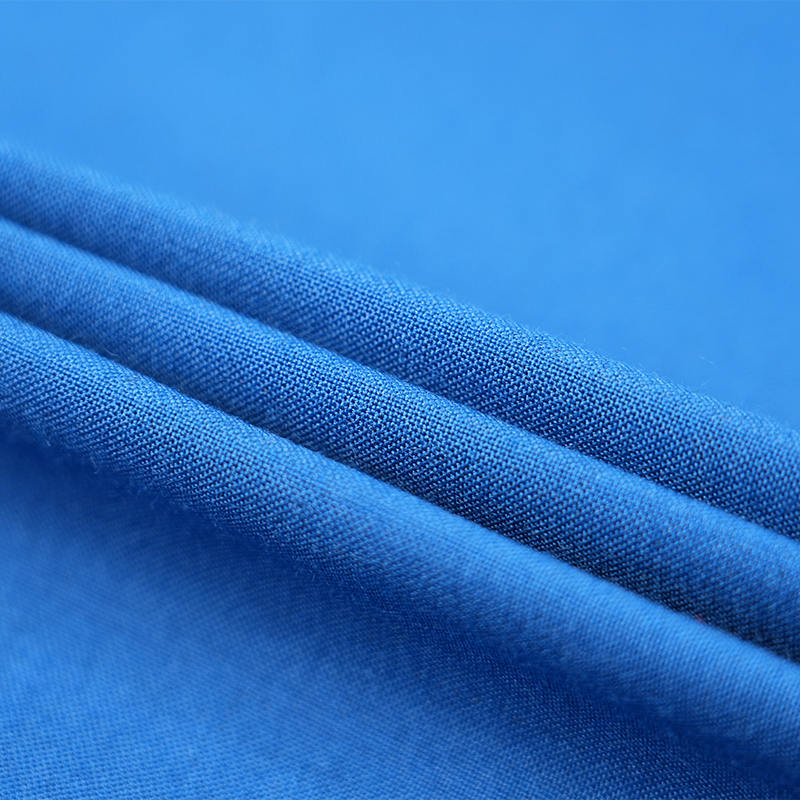

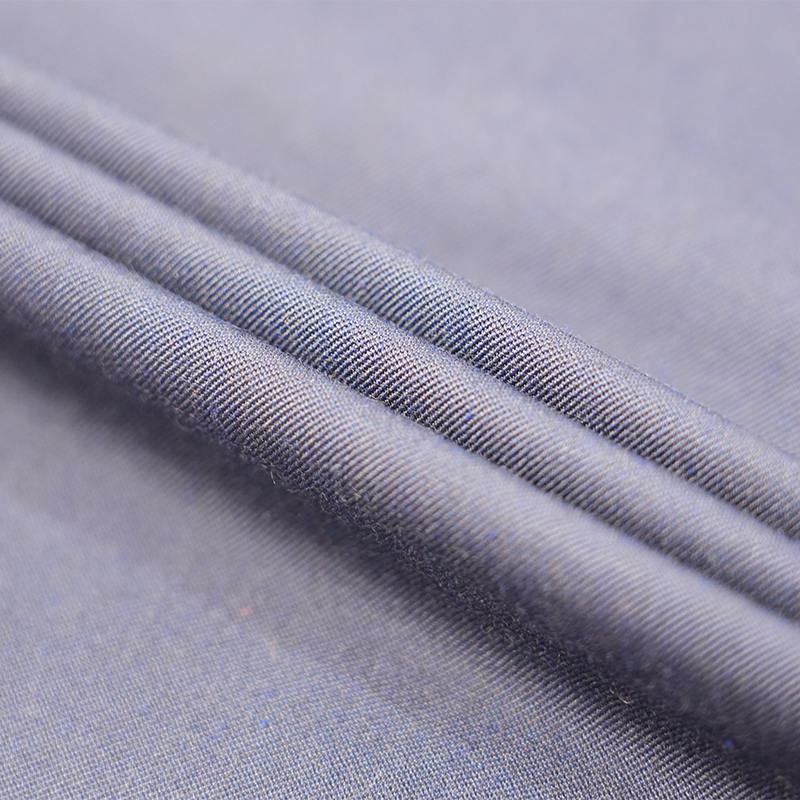

Available colors.

National flag red, refining blue, sales blue.

Standard: GB8965,1

GB8965,1-2020B grade

GB12014

NFPA2112

EN11612

EN11611

Sinopec

Color: Color customized

Weight: 150gsm-250gsm

Weave: Twill/Plain/Ripstop

Full width: 150cm

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى