| AMT-L01 | AMT-L02 | AMT-L03 | AMT-L04 | AMT-L05 | AMT-L11 | AMT-L12 | |

| Color | Color customized | Color customized | Color customized | Color customized | Color customized | Color customized | Color customized |

| Weight | 280gsm | 360gsm | 320gsm/350gsm | 370gsm | 250-370gsm | 260gsm | 330gsm |

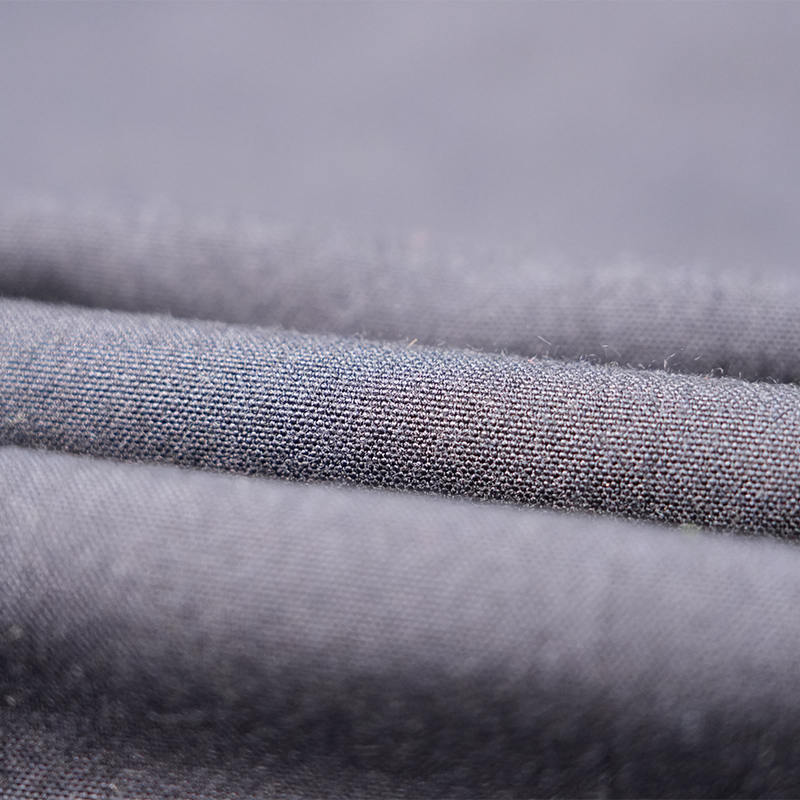

| Weave | Twill | Twill | Twill | Twill | Twill | Twill | Twill |

| Full width | 150cm | 150cm | 150cm | 150cm | 150cm | 150cm | 150cm |

AMT Twill FR molten metal splash protective fabric is a high-performance flame-retardant (FR) fabric designed specifically for the metallurgy, foundry, and metalworking industries. It protects against the risk of high-temperature burns caused by splashing molten aluminum, iron, and other metals. Whether in steel mills, aluminum smelters, or metal foundries, this 3H molten metal splash fabric provides workers with the ultimate in reliable protection, ensuring safety and operational efficiency.

Advantages:

Molten Metal Splash Protection:

This fabric utilizes advanced flame-retardant technology to effectively prevent burns caused by hot molten metal splashing.

Compliant with EN ISO 11612 standards, specifically ratings D (molten aluminum splash protection) and E (molten iron splash protection), it provides reliable, internationally certified protection.

It offers excellent thermal insulation and anti-drip properties, preventing molten metal from adhering and penetrating, minimizing risk.

Versatile Fiber Blends:

Our fabrics are expertly blended with high-performance fibers such as wool, cellulose, aramid, viscose, and Tencel, using various formulations. These fabrics offer flame retardancy while balancing comfort, strength, and durability.

High Comfort and Breathability:

Excellent breathability wicks away perspiration, keeping workers dry and comfortable during long shifts.

The twill weave provides a pleasant feel and flexibility, ensuring smooth movement.

Long-Lasting Durability:

They resist the wear and tear of demanding work, effectively extending the life of protective clothing and reducing costs.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى