| QFU-01 | QFU-02 | QFU-03 | QFU-09 | PFA-D72 | PIN-001~PIN-003 | |

| Color | Color customized | Color customized | Color customized | Color customized | Color customized | Color customized |

| Weight | 120gsm-250gsm | 275gsm/300gsm | 200gsm-300gsm | 380gsm | 150gsm-220gsm | 120gsm-220gsm |

| Weave | Twill/Plain/Ripstop | Twill | Twill/Plain | Plain | Twill/Plain | Twill/Plain |

| Full width | 150cm | 150cm | 150cm | 150cm | 150cm | 150cm |

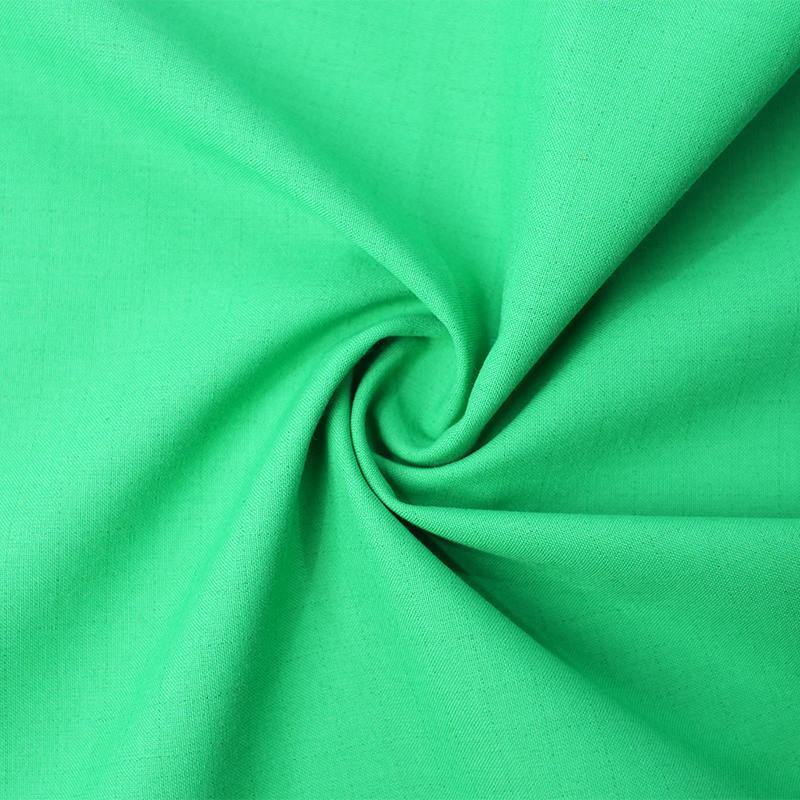

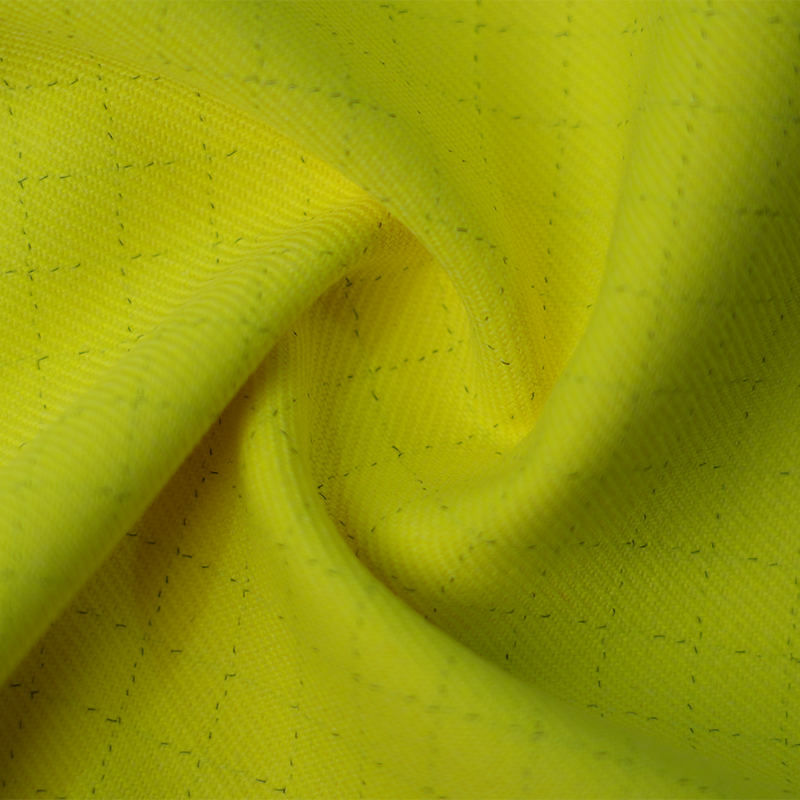

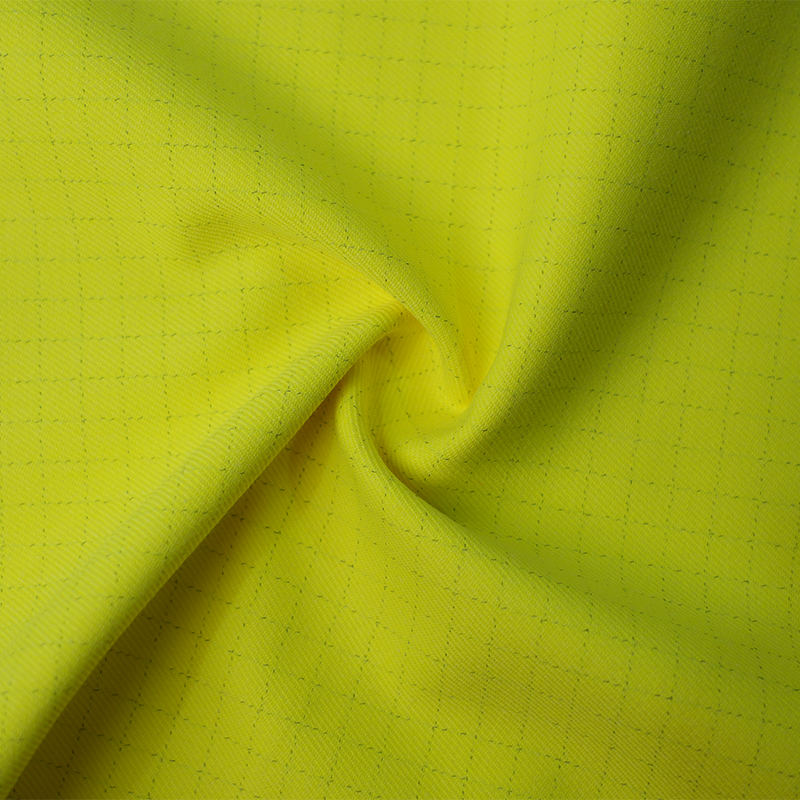

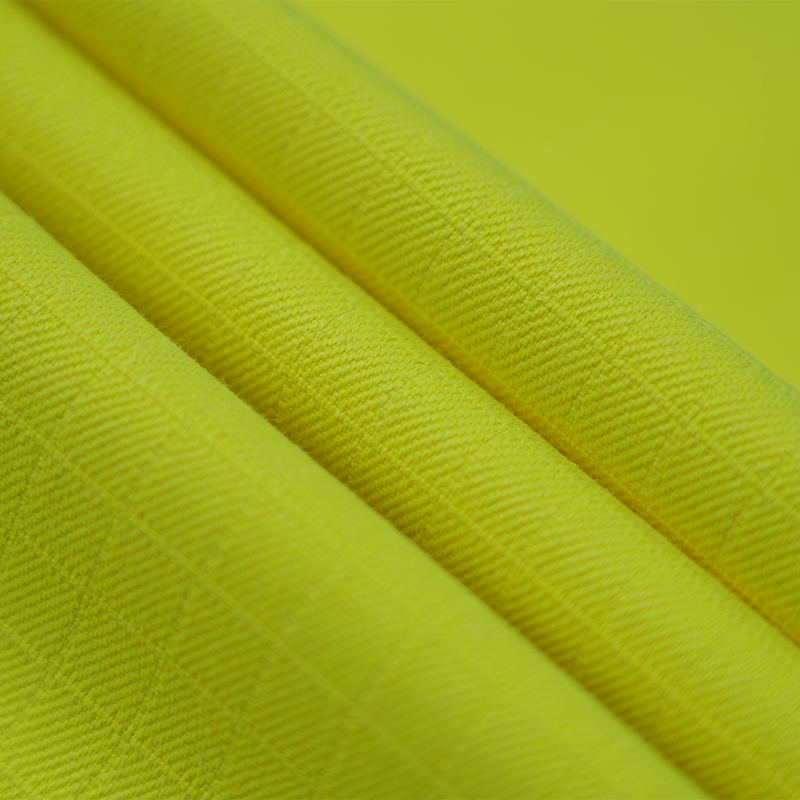

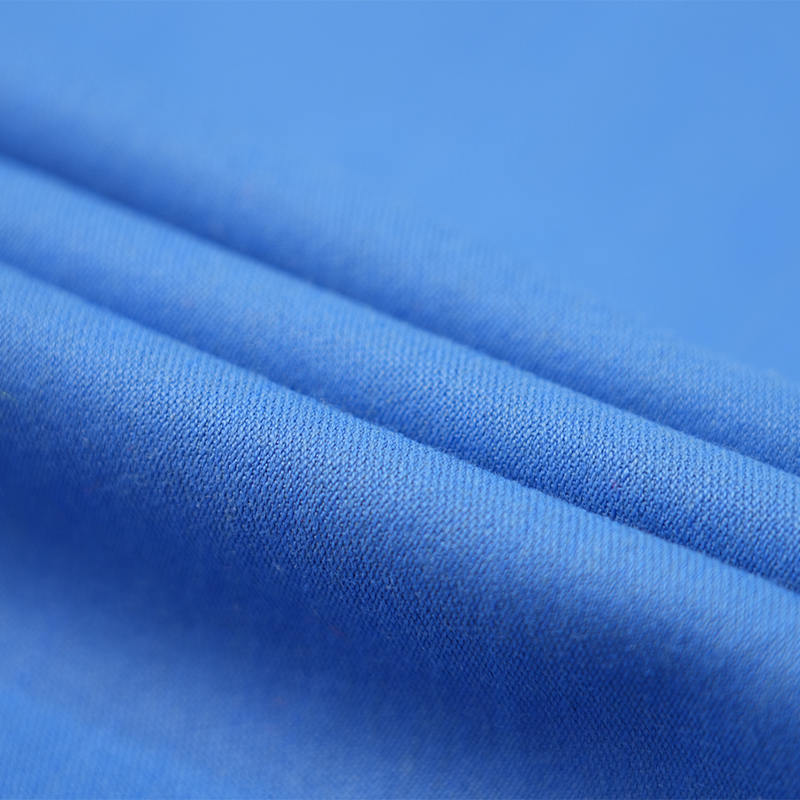

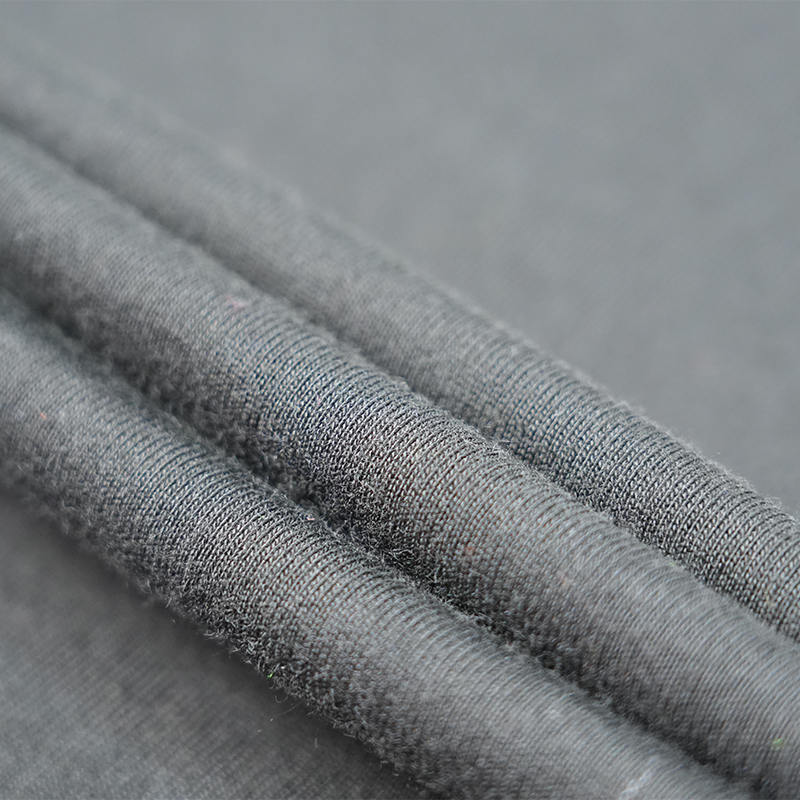

Modacrylic blended FR fabric is a high-performance flame-retardant fabric suitable for oil and gas protection applications, offering excellent flame retardancy, anti-static properties, and comfort.

Product Features:

Flame Retardancy: The fabric offers excellent flame retardancy, providing added protection and is suitable for workwear in the power, oil, and gas industries.

Thermal Protection: Modacrylic blended FR fabric effectively resists heat transfer, providing critical protection in flash fires and reducing the risk of burns.

Comfort: The blend of cotton and other ingredients in the fabric provides excellent moisture-wicking properties, making it comfortable to wear and suitable for extended work.

Anti-Static: All formulas contain anti-static fibers that effectively dissipate static charges, preventing sparks and explosions caused by static buildup – crucial in flammable and explosive environments.

Excellent Color Fastness: Specially dyed for a durable, fade-resistant color, the fabric maintains its appearance even in harsh environments.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى