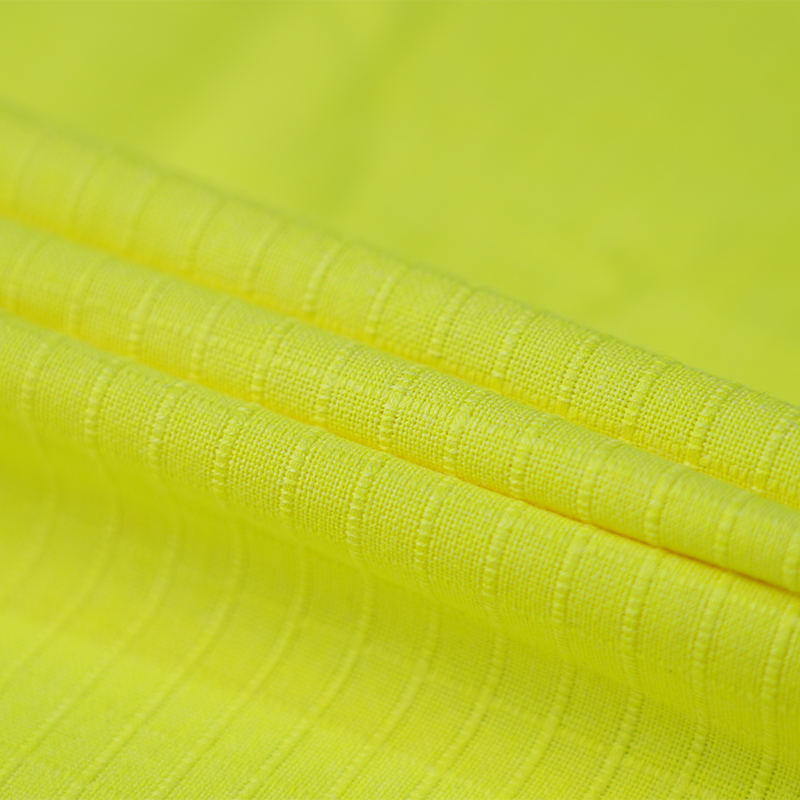

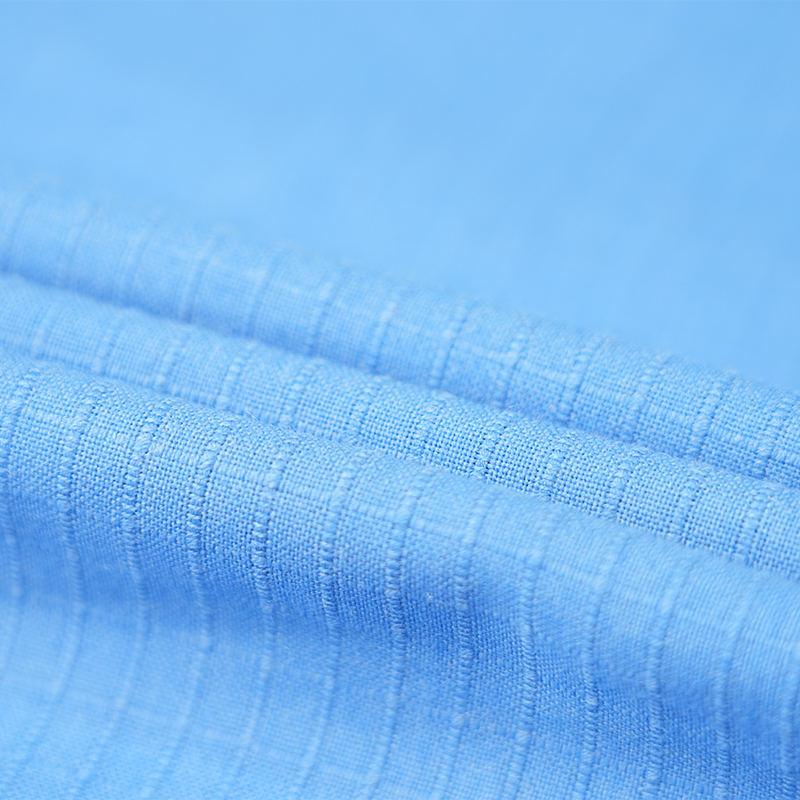

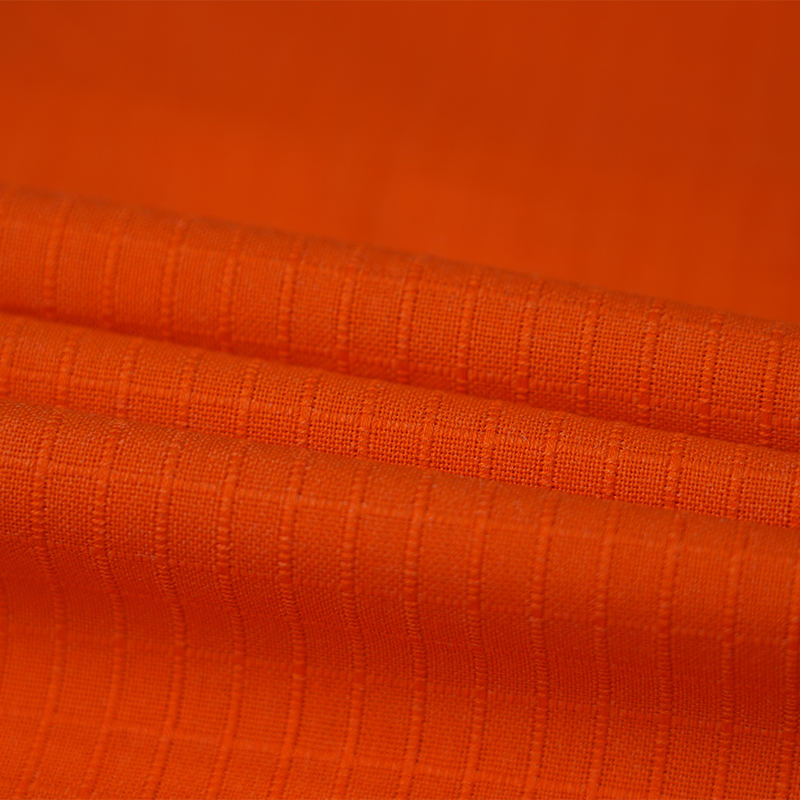

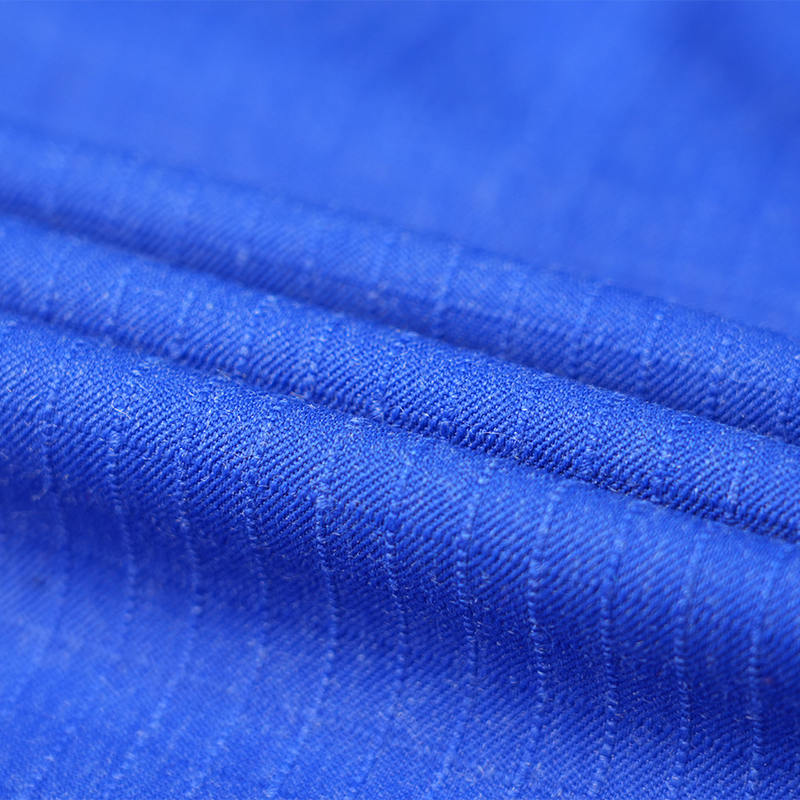

Twill/Plain/Ripstop Electric Arc Protection FR fabric: Innovative solution for power safety protection

Core function of the product

Twill/Plain/Ripstop Electric Arc Protection FR fabric is a composite protective fabric that integrates twill, plain and tear-resistant structures. It is specially designed for high-risk working environments in the power industry and has the following core functions:

Arc protection: It can withstand the instantaneous high temperature generated by 8-40kV arc flash explosion

Flame retardant and fireproof: Limiting oxygen index LOI ≥ 34, meeting EN ISO 11612 highest protection level

Mechanical protection: tear strength ≥ 1000N, wear resistance index ≥ 80000 times

Electrostatic protection: surface resistance 10⁶-10⁹Ω, electrostatic decay time ≤ 0.3 seconds

Innovative structural principle

Composite woven structure:

Twill layer (45°): Aramid 1414/flame-retardant viscose blended to improve multi-directional tear resistance

Plain layer: High-density glass fiber weaving to provide uniform thermal radiation protection

Tear-resistant mesh: UHMWPE ultra-high molecular weight polyethylene grid reinforcement

Intelligent protection system:

Arc response: temperature-sensitive aerogel layer (starting at 70°C, expansion rate 500%)

Thermal management: phase change material microcapsules (heat absorption capacity 220J/g)

Damage warning: conductive fiber sensor network (damage positioning accuracy 5m m)

Multifunctional treatment:

Triple anti-finishing: water-repellent, oil-repellent, anti-melting droplet (contact angle ≥ 150°)

Infrared stealth: low emissivity coating (ε≤0.25)

UV protection: nano zinc oxide treatment (UPF50+)

Durability:

Performance retention rate ≥95% after 100 industrial washings

Strength retention rate ≥90% after 500h of UV irradiation

Abrasion test 100,000 times (Martindale method)

Application areas

Ultra-high voltage power operation:

1000kV ultra-high voltage live operation clothing

Intelligent inspection equipment for substations

Protective clothing for DC converter stations

New energy fields:

High voltage maintenance of photovoltaic power stations

Overhaul of wind turbines

Battery room protection for energy storage power stations

Special industries:

Operation protection of arc furnaces

Tooling for aluminum electrolysis workshops

Military electronic assembly

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى