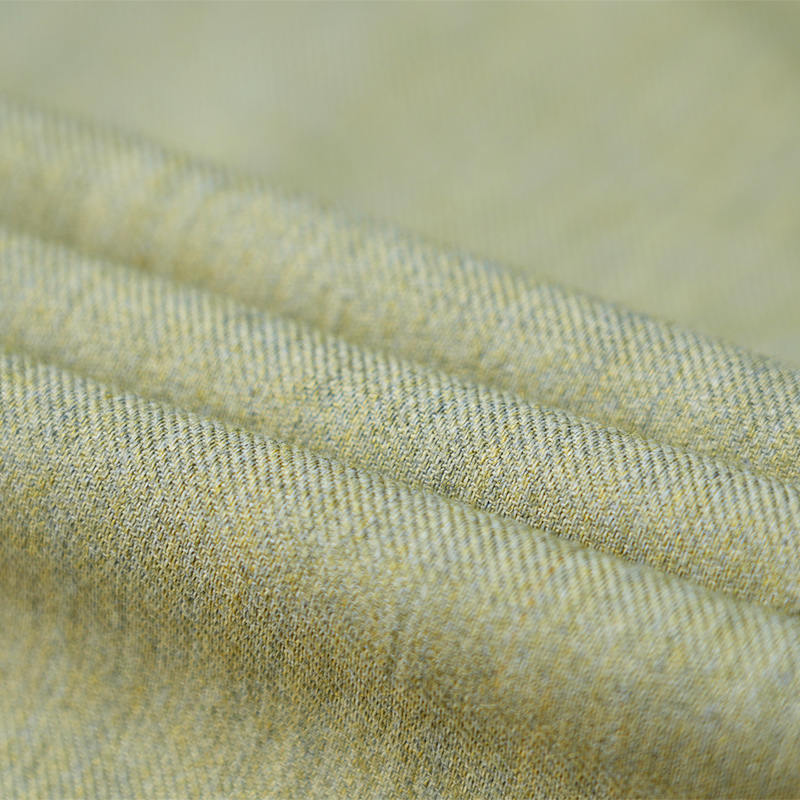

Twill flame retardant welding protective fabric: a solution for welding safety protection

Product function

Twill flame retardant welding protective fabric is a high-performance protective material specially developed for welding working environment, with the following functions:

Welding spark protection: effectively block welding spatter above 3000℃

Flame retardant and fireproof: limit oxygen index LOI ≥ 34, prevent flame spread

Thermal radiation isolation: reduce welding heat conduction and maintain working comfort

Protection principle

Twill reinforced structure:

Use 45° twill weaving process to form a dense protective network

High-density aramid/glass fiber blended (yarn density ≥ 240 strands/inch)

Three-dimensional structure enhances spark rebound effect

Complex Combined protection system:

Outer layer: aluminum foil composite coating (reflectivity ≥ 90%)

Middle layer: ceramic silicone insulation layer (temperature resistant 1800℃)

Inner layer: flame-retardant cotton lining (moisture-absorbing and breathable)

Intelligent protection mechanism:

Automatic shedding of welding spatter (contact angle ≥ 160°)

Temperature-sensitive warning system (discoloration starts at 500℃)

Elastic edge design (suitable for various welding postures)

Main application areas

Industrial welding:

Steel structure welding protection

Pipeline welding operation

Shipbuilding welding

Special welding:

Thermite welding

Plasma cutting

Laser welding

Maintenance areas:

Equipment maintenance welding

Railway track welding

Pressure vessel maintenance

Product core advantages

Professional protection:

Passed EN ISO 11611, NFPA 2112 and other international certifications

Four-layer composite protective structure ensures safety

Durable:

Performance retention rate ≥97% after 100 washings

Anti-welding slag adhesion

Easy to use:

Lightweight design (30% lighter than traditional products)

Quick donning system

Environmentally friendly and safe:

No asbestos, no harmful substances

OEKO-TEX® environmental certification

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى