Color: Color customized

Weight: 340gsm

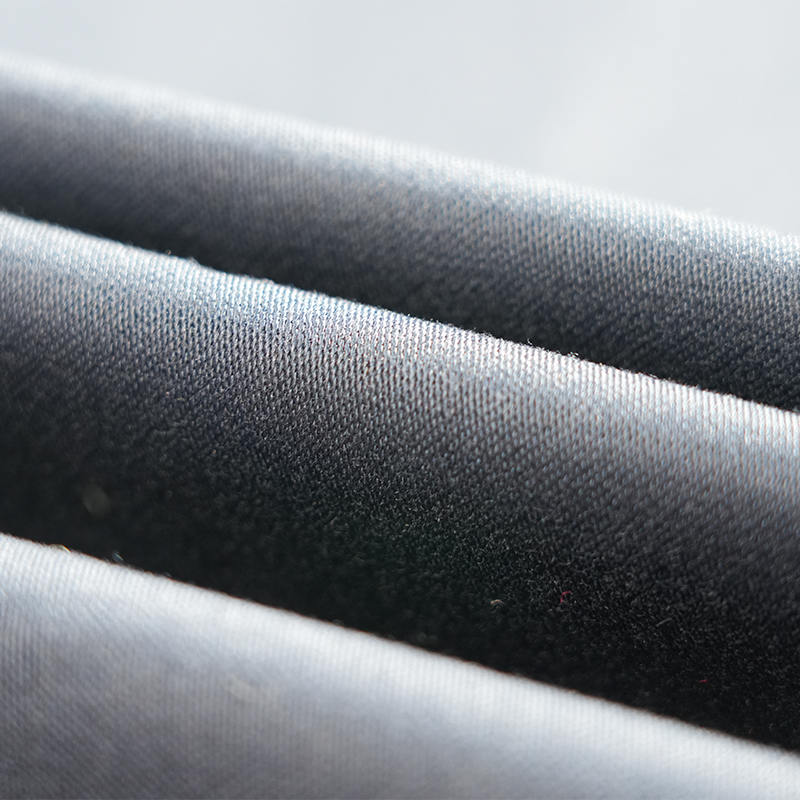

Weave: Sateen

Full width: 150cm

AFT-H02 Sateen FR welding protective fabric is designed to meet the stringent safety standards of the welding and mechanical industries. Featuring an advanced flame-retardant finish, it effectively protects against arc damage, metal splash, and short-term heat exposure, fully complying with the EN ISO 11611 welding protection standard. Its stable and reliable flame retardancy provides a solid safety barrier for workers exposed to sparks, high temperatures, and dripping molten metal.

The Sateen Weave fabric gives AFT-H02 a smoother, softer feel and improved drape, significantly enhancing wearer comfort.

The natural cotton content maintains excellent moisture wicking and breathability, keeping workers dry and reducing stuffiness even during intense work.

The compact Sateen Weave construction provides excellent abrasion and tear resistance, effectively resisting the friction and wear of everyday work, extending the life of protective clothing and reducing costs.

It is widely suitable for a variety of high-risk operations, including heavy industrial welding, metal cutting, and repair, providing reliable, all-round protection for workers.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى