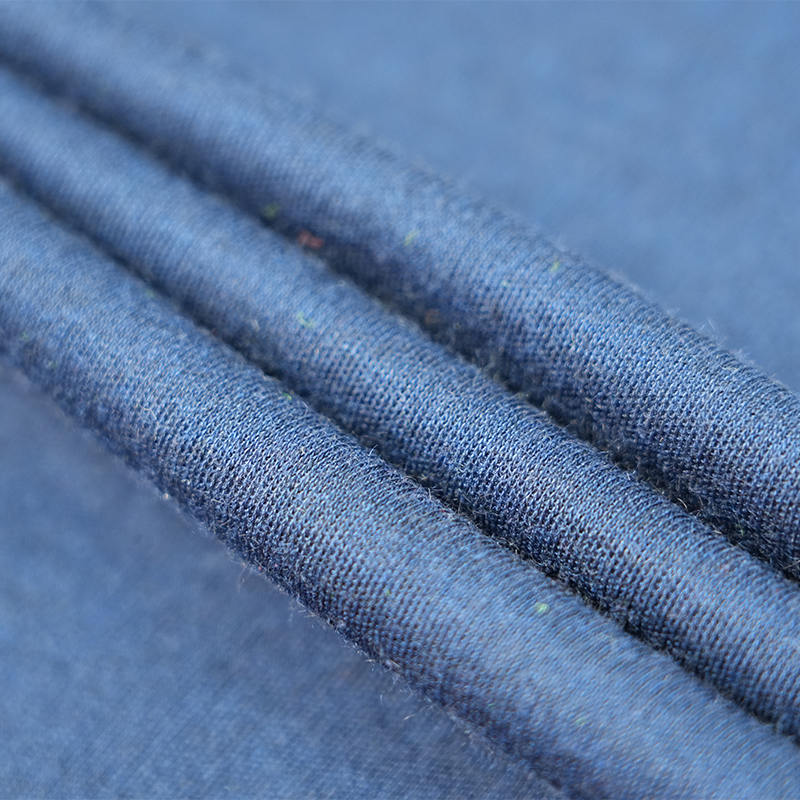

Flame retardant double-sided knitted fabric: a combination of double protection and comfort

Product features:

Flame retardant double-sided knitted fabric is a new generation of intelligent protective material developed using innovative double-layer weaving technology. Through the unique double-sided structural design, it achieves the dual functions of "one side protection and one side comfort". This product breaks through the performance limitations of traditional single-layer flame retardant fabrics and provides a safer and smarter material choice for special protective clothing.

Technical principle

Double-layer composite structure system:

Outer layer: high-density woven layer (using aramid 1414/flame-retardant polyester blend)

Inner layer: breathable and comfortable layer (flame-retardant viscose/cotton blend)

Middle: nano-aerogel thermal insulation film

Intelligent flame retardant mechanism:

Outer layer: quickly carbonizes when exposed to fire to form a dense protective layer (carbonization rate ≥85%)

Middle layer: thermal expansion material automatically thickens at high temperature (starts at 70℃)

Inner layer: phase change material adjusts microclimate (temperature fluctuation ±2℃)

Weaving process:

Double-sided synchronous weaving technology (error ≤0.5mm)

Three-dimensional yarn feeding system ensures balanced tension

Intelligent temperature control weaving (real-time adjustment of yarn density)

Comfortable experience:

Breathable difference design (outer layer 800L/m²/s, inner layer 2500L/m²/s)

Humidity regulation function (inner layer moisture absorption rate ≥0.25g/h)

Bidirectional stretch rate ≥45% (active 60% increase in freedom of movement)

Durability:

Protective performance retention rate after multiple washings ≥98%

Abrasion test ≥80,000 times (outer layer)/50,000 times (inner layer)

UV-resistant UPF50+ (outer layer) + antibacterial rate ≥99% (inner layer)

Typical application scenarios

High-risk industrial fields:

High-temperature work clothes in the metallurgical industry (contact temperature ≤800℃)

Chemical protective clothing in the chemical industry (resistant to 300 chemicals)

Live work clothes in the power industry (ATPV≥15cal/cm²)

Special protection market:

Protective clothing for aviation firefighters (flame resistance time ≥30 seconds)

Deep-sea operation equipment (water pressure resistance 5MPa)

Polar scientific research clothing (-50℃ insulation)

High-end civilian fields:

Intelligent temperature control firefighting home clothes (response time ≤3 seconds)

Special vehicle seat fabrics (flame retardant + wear resistant)

Medical protective textiles (antibacterial + flame retardant)

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى