Embracing Innovative Technology for a Secure Future

FR Knitted Fabric Manufacturers

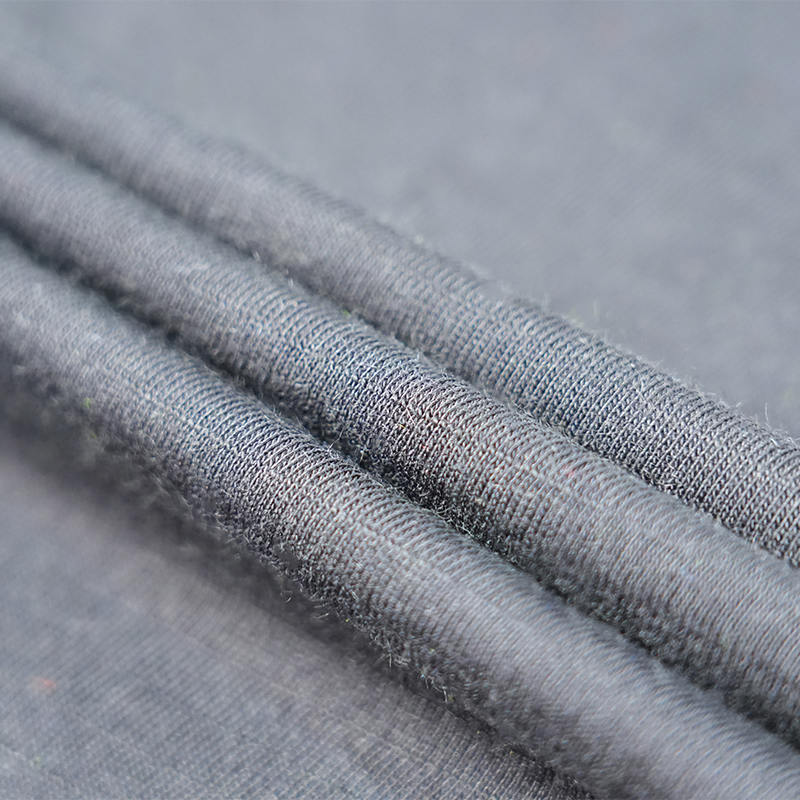

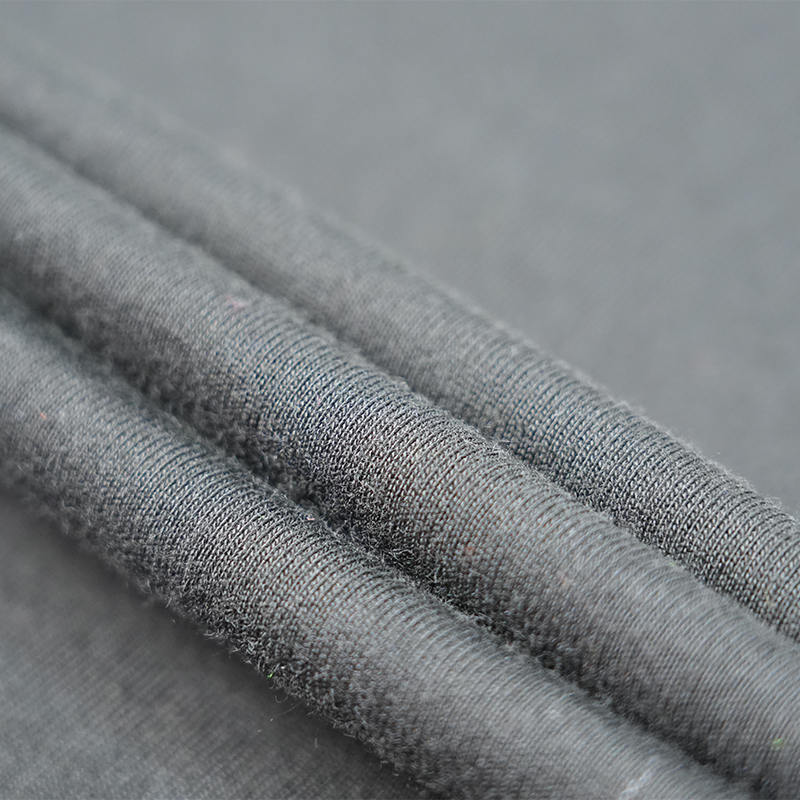

FR Knitted Fabric Description:

Inherent Flame Retardant Properties

3H uses inherently flame-retardant fibres such as meso-aramids, FR viscose and modified acrylics to ensure that fabrics retain their excellent flame-retardant properties even after 100 washes, providing long-lasting and stable protection.

Versatile Options

3H offers fabrics ranging from lightweight composite flame retardant fabrics at 60g/m² to extreme cold insulating fabrics at 600g/m² to meet the needs of different applications. Our knitted fabrics for underwear, polo shirts, T-shirts, fleeces and softshell jackets are available in a wide range of combinations of modified acrylics, Lenzing FR fibres, aramids, cotton, Tencel, wool, nylon and polyester, to ensure a high-level of protection and comfort.

Comfortable and breathable

The unique structure of cellulosic fibres regulates moisture and enhances the breathability of the fabric, helping to maintain the body's natural temperature balance. Our FR viscose/aramid knitted fabrics and modified acrylic knitted fabrics are soft and comfortable, with a better tactile feel than traditional flame-retardant cotton.

Superior Arc Protection

3H knit fabrics contain para-aramid fibres, which provide excellent protection against electric arcs due to their high-temperature resistance and flame-retardant properties. Even in lightweight designs, it maintains a high ATPV value to ensure efficient safety.

Anti-pilling and durability

The fabric has been treated with a special process that significantly improves anti-pilling properties and maintains a smooth and delicate surface after multiple washes for a longer service life.

Easy care

3H knitted fabrics can be home-washed at 60°C, with low shrinkage and tumble drying support, keeping garments looking as good as new for a long time.

Excellent price/performance ratio

3H is committed to providing cost-effective products that combine European quality with Asian price advantages to meet the diversified needs of our customers.

FABRICS MANUFACTURER

-

0+

0+Enterprise establishment

-

0+

0+Employees

-

2026-01-30High Visibility Flame Retardant Fabric: Is It the Ultimate Safety Solution for Hazardous Workplaces?High visibility flame retardant fabric is widely used in industrial safety clothing, protective uniforms, and emergency response gear. By combining fi...

-

2026-01-23We are pleased to announce that our General Manager, Mr. An Biao, participated as a Council Member in the 2nd Session of the 5th Council of the China ...

-

2026-01-22When working in environments with potential fire hazards or low visibility, safety is paramount. One of the key ways to stay safe is by wearing the ri...

-

2026-01-19Our General Manager, An Biao, is representing the company at the 2025 Annual Meeting of the Haian City Industrial Economic Federation today.

Flame-retardant protective equipment is a crucial barrier to worker safety in various high-risk work environments. While traditional woven flame-retardant fabrics offer excellent protection, they often lack comfort and freedom of movement. The emergence of flame-retardant knitted fabrics perfectly addresses this dilemma. Through a unique weaving process and a combination of high-performance fibers, they meet stringent flame-retardant standards while offering excellent elasticity and breathability, making them an ideal choice for modern protective equipment.

Flame-retardant knitted fabrics utilize a specialized weave structure that maintains tightness while offering excellent stretchability. This structure not only adapts to various postures during movement but also quickly rebounds when subjected to external forces, preventing the risk of tearing caused by strenuous exercise. Their flame-retardant properties stem from specially treated fiber materials, such as flame-retardant polyester, flame-retardant viscose, or aramid blends. These fibers resist melting and dripping in high-temperature environments, instead forming a stable carbonized layer that effectively isolates heat transfer. Compared to traditional woven flame-retardant fabrics, the knitting process imparts improved breathability and moisture-wicking properties, significantly enhancing comfort for extended wear.

These fabrics have a wide range of applications. In traditionally high-risk industries like the petrochemical industry and the electric power industry, flame-retardant knitted fabrics are used to make close-fitting protective underwear, headgear, and socks, providing workers with basic yet crucial protection. In firefighting and emergency rescue, their excellent elasticity and breathability make them a preferred material for inner protective clothing, effectively reducing fatigue caused by stuffiness and constriction. Furthermore, flame-retardant knitted fabrics are gradually entering the civilian market, such as children's pajamas and high-speed rail seat fabrics, adding a layer of safety to daily life.

With increasing demand for more comfortable working environments, flame-retardant knitted fabrics are experiencing rapid growth. 3H.Safety.Technology, a manufacturer of flame-retardant functional fabrics under the brand "3H.Safeloya®," is dedicated to product research and development and fabric production. As a professional flame-retardant fabric manufacturer and workwear manufacturer, our products are widely used in various industries, including the petroleum, petrochemical, chemical, gas stations, electric power, coal mining, steel, metallurgy, and machining.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى