| PIK-SM11 | PIK-SM14 | PIK-D01 | PIK-D02 | PIK-D07 | PIK-Y01 | |

| Color | Color customized | Color customized | Color customized | Color customized | Color customized | Color customized |

| Weight | customized | customized | customized | 400gsm | 375gsm | 320gsm |

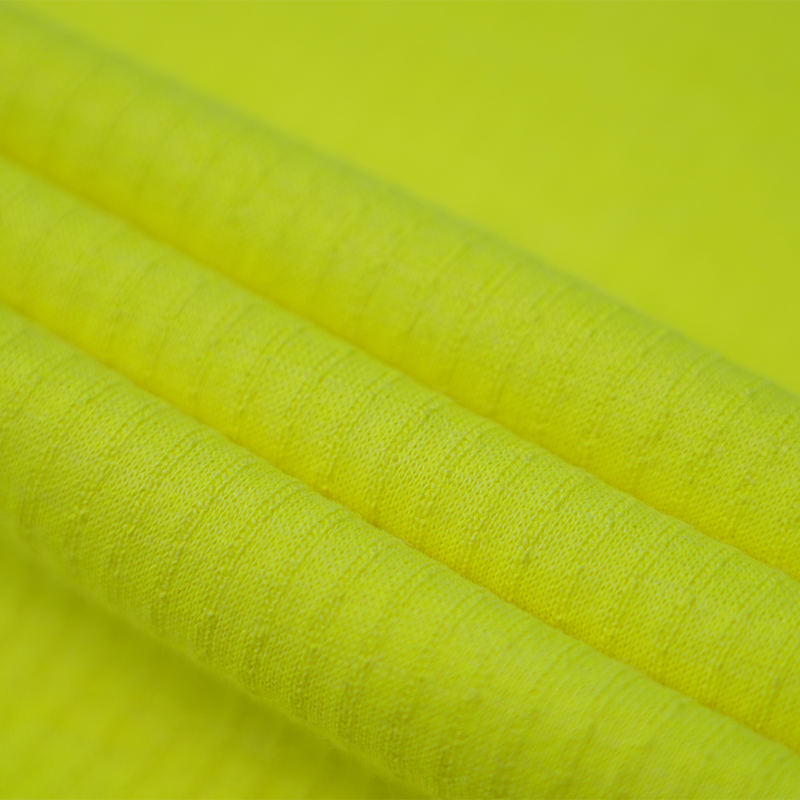

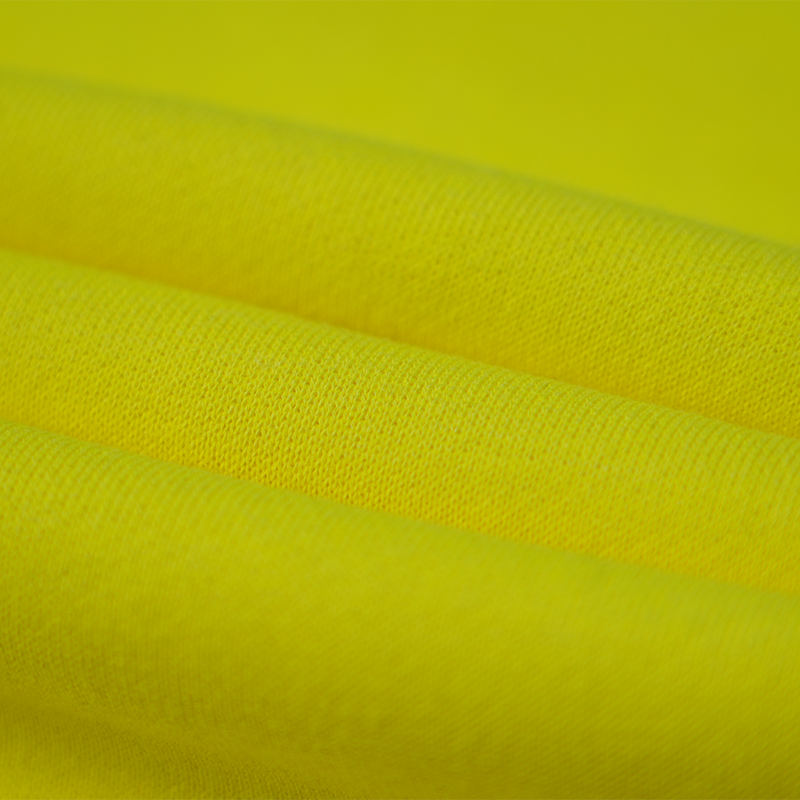

| Weave | knitted | Double-layer Square Pattern Interlock Fabric | Square FleeceInterlock Fabric | Single-face FleeceFabric | Single-face FleeceFabric | Double Brushed Single-sided Sherpa Fleece |

| Full width | 170cm | 170-180cm | 170-180cm | 170-180cm | 170-180cm | 170-180cm |

Inherent Flame Retardant Properties

3H uses inherently flame-retardant fibres such as meso-aramids, FR viscose and modified acrylics to ensure that fabrics retain their excellent flame-retardant properties even after 100 washes, providing long-lasting and stable protection.

Comfortable and breathable

The unique structure of cellulosic fibres regulates moisture and enhances the breathability of the fabric, helping to maintain the body's natural temperature balance. Our FR viscose/aramid knitted fabrics and modified acrylic knitted fabrics are soft and comfortable, with a better tactile feel than traditional flame-retardant cotton.

Superior Arc Protection

3H knit fabrics contain para-aramid fibres, which provide excellent protection against electric arcs due to their high-temperature resistance and flame-retardant properties. Even in lightweight designs, it maintains a high ATPV value to ensure efficient safety.

Anti-pilling and durability

The fabric has been treated with a special process that significantly improves anti-pilling properties and maintains a smooth and delicate surface after multiple washes for a longer service life.

Easy care

3H knitted fabrics can be home-washed at 60°C, with low shrinkage and tumble drying support, keeping garments looking as good as new for a long time.

Excellent price/performance ratio

3H is committed to providing cost-effective products that combine European quality with Asian price advantages to meet the diversified needs of our customers.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى