FABRICS MANUFACTURER

-

0+

0+Enterprise establishment

-

0+

0+Employees

-

2026-01-30High Visibility Flame Retardant Fabric: Is It the Ultimate Safety Solution for Hazardous Workplaces?High visibility flame retardant fabric is widely used in industrial safety clothing, protective uniforms, and emergency response gear. By combining fi...

-

2026-01-23We are pleased to announce that our General Manager, Mr. An Biao, participated as a Council Member in the 2nd Session of the 5th Council of the China ...

-

2026-01-22When working in environments with potential fire hazards or low visibility, safety is paramount. One of the key ways to stay safe is by wearing the ri...

-

2026-01-19Our General Manager, An Biao, is representing the company at the 2025 Annual Meeting of the Haian City Industrial Economic Federation today.

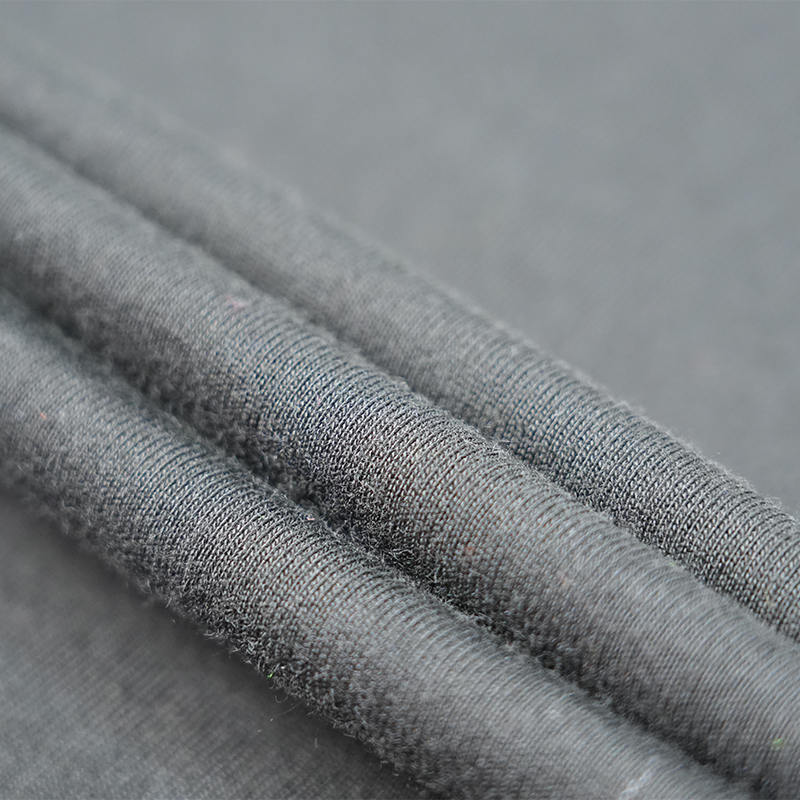

In industrial protective clothing, specialty apparel, and everyday safety apparel, traditional flame-retardant materials often struggle to balance protective performance and comfort. Modacrylic and cotton blended fabrics, through innovative fiber modification and scientific blending technologies, successfully achieve a perfect combination of flame retardancy and natural comfort, offering a new material option for protective clothing. This fabric retains the moisture-wicking and breathable properties of cotton fibers while imparting the long-lasting flame retardant protection of modified acrylic, redefining safety standards.

The core advantage of modified acrylic and cotton blended fabrics lies in their unique "dual-action protection" mechanism. By blending specially flame-retardant acrylic fibers with natural cotton fibers in an optimized ratio, the fabric creates a synergistic protective network at the molecular level. Modacrylic fibers rapidly expand and carbonize at high temperatures, forming a dense thermal barrier; while the flame-retardant-treated cotton fibers dehydrate and carbonize, effectively delaying combustion. This dual-protection mechanism not only enables the fabric to pass international flame retardancy standards such as EN ISO 11612, but also significantly improves the reliability and durability of its protection. Compared to traditional post-treated flame-retardant fabrics, modified acrylic-cotton blended fabrics maintain stable flame-retardant properties after repeated washings, resolving the industry's challenge of protective effectiveness fading over time.

This fabric has extensive and diverse applications. In the energy and power industry, protective workwear made from it provides all-weather safety for substation workers. Explosion-proof equipment in the petrochemical industry uses this material, meeting stringent anti-static requirements while maintaining flame-retardant properties. More notably, in industries requiring prolonged wear of protective clothing—such as metallurgy and glassmaking, where high-temperature environments are common—the excellent breathability and moisture-wicking properties of modified acrylic-cotton blended fabrics significantly enhance wearer comfort and effectively reduce heat stress.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى