Embracing Innovative Technology for a Secure Future

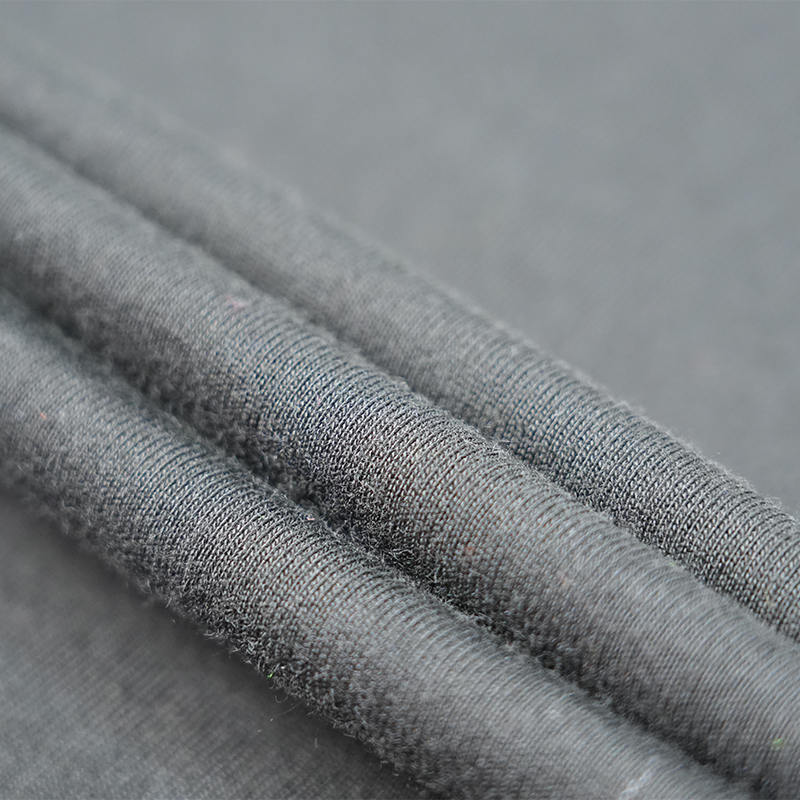

Modacrylic Blended Fabric Manufacturers

-

-

-

-

-

-

QFU-05 Modacrylic/Polyester/Cellulose/Super fiber/Anti-static FR Hi-Vis Fabric

-

PIK-SM11 Modacrylic/Polyester/Cellulose/Super fiber FR Hi-Vis Fabric

FABRICS MANUFACTURER

-

0+

0+Enterprise establishment

-

0+

0+Employees

-

2026-01-30High Visibility Flame Retardant Fabric: Is It the Ultimate Safety Solution for Hazardous Workplaces?High visibility flame retardant fabric is widely used in industrial safety clothing, protective uniforms, and emergency response gear. By combining fi...

-

2026-01-23We are pleased to announce that our General Manager, Mr. An Biao, participated as a Council Member in the 2nd Session of the 5th Council of the China ...

-

2026-01-22When working in environments with potential fire hazards or low visibility, safety is paramount. One of the key ways to stay safe is by wearing the ri...

-

2026-01-19Our General Manager, An Biao, is representing the company at the 2025 Annual Meeting of the Haian City Industrial Economic Federation today.

In the field of protective materials, the performance limitations of individual fibers have always been a bottleneck for technological breakthroughs. Modified acrylic blended fabrics, through molecular-level structural design and integrated multi-fiber systems, create a new protective system that combines intrinsic flame retardancy, environmental adaptability, and wear comfort. This is reshaping the material application landscape from industrial safety to everyday protection. This intelligent material, which leverages chemical modification technology and achieves functional amplification through precise blending, represents the forefront of modern protective technology towards multifunctional integration.

The revolutionary breakthrough of modified acrylic blended fabrics lies in their "three-in-one" protective architecture. By embedding phosphorus-nitrogen synergistic flame-retardant groups within the polymer chain, the modified acrylic fibers achieve intrinsic flame retardancy, with a Limiting Oxygen Index (LOI) exceeding 32%. When exposed to fire, they form an expanding char layer without producing melt droplets. When blended with conductive fibers, static charges are instantly dissipated through interfiber capacitance, maintaining a stable surface resistance within the 10^6-10^9 Ω range. When combined with moisture-wicking fibers, the wicking effect allows for moisture permeability exceeding 4500 g/m²/24h, fundamentally resolving the stuffiness associated with traditional flame-retardant fabrics. Even more groundbreaking is the use of gradient blending technology, which creates a functional gradient distribution across the fabric's cross-section: flame retardant, conductive, and moisture permeable, achieving optimized performance at the microscale.

The industrial application of this material is catalyzing a new generation of protective solutions. Explosion-proof clothing for offshore oil platforms utilizes a blend of modified acrylic and cuprammonium fibers. While maintaining EN1149 antistatic standards, it also achieves a 60% increase in strength retention in salt spray environments. Smart grid inspection clothing incorporates modified carbon nanotube fibers, enabling both arc protection and electromagnetic shielding. In the consumer sector, flame-retardant home textiles made from a blend of modified acrylic and Lyocell are OEKO-TEX certified and naturally antibacterial. Interior fabrics for new energy vehicles utilize their anti-melting properties and low smoke density to significantly enhance driver safety. In the special operations sector, spectrally modulated modified acrylic blended camouflage fabrics have achieved a technological breakthrough in infrared-radar multi-spectrum stealth. As a leading manufacturer of flame-retardant fabrics, 3H Safety Technology Co., Ltd. not only produces high-quality flame-retardant fabrics but also contributes to the development and approval of industry standards. Our team of experts has participated in the development of numerous domestic and international flame-retardant fabric standards, and our products are manufactured and tested in strict accordance with these standards.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى