In many industries, especially construction, road construction, petrochemicals, mining, and emergency rescue, the safety of nighttime operations is always a key concern for businesses. The low light conditions, frequent movement of vehicles and machinery, and frequent hazardous operations significantly increase the safety risks for workers. To reduce the accident rate, more and more companies are adopting high-visibility flame-retardant fabrics for workwear and protective equipment to improve safety during nighttime work.

1. Overview of High-Visibility Flame-Retardant Fabrics

High-visibility flame-retardant fabric is a functional fabric that combines reflective visibility and flame-retardant properties. While ensuring visibility at night, it also provides basic protection in flammable or high-temperature environments. Key features include:

High Reflectivity

The fabric surface typically uses fluorescent colors (such as orange and yellow) and reflective strips, allowing it to be seen from a distance in low-light conditions.

By reflecting vehicle headlights or other light sources, it ensures that workers are clearly visible.

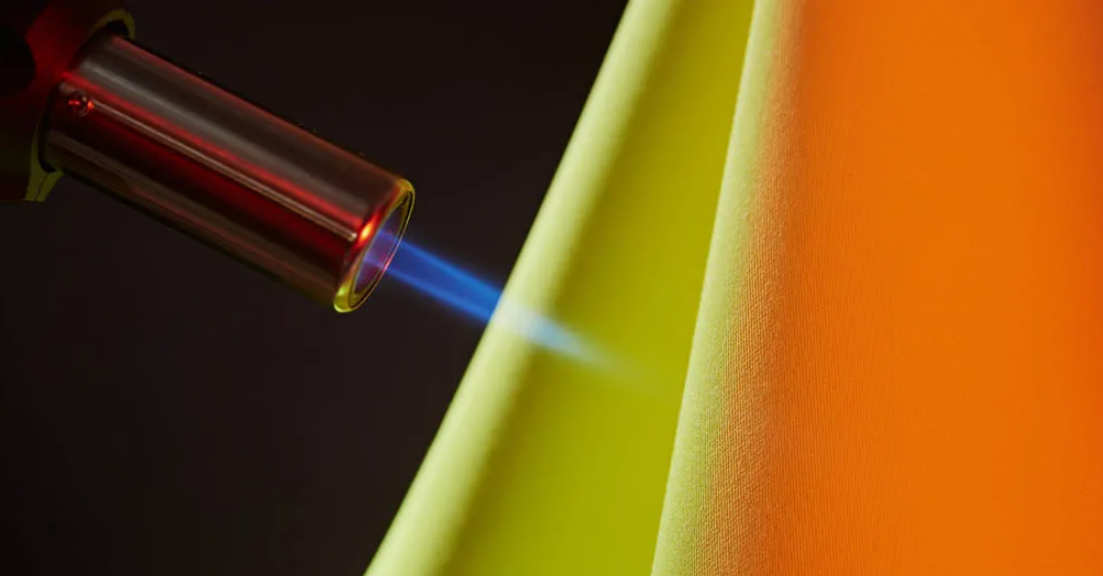

Flame Retardant Properties

The fabric is treated with special flame retardant treatment or made from flame-retardant fibers, such as aramid, or a blend of cotton and flame-retardant polyester.

Even if the fabric comes into contact with a fire source, it can prevent the spread of fire in a short time, giving workers time to escape.

Durability and Comfort

High-visibility flame-retardant fabrics combine strength and breathability, making them suitable for long-term wear.

Most products are lightweight and do not affect the worker's operational flexibility.

2. The Importance of High-Visibility Flame-Retardant Fabrics in Nighttime Work

(1) Improving Worker Visibility

Low visibility is one of the main causes of accidents during nighttime operations. Wearing workwear made of high-visibility flame-retardant fabric can significantly increase the visibility of workers in dark environments.

Reducing traffic accident risks: For road construction workers or traffic police officers working at night, the reflective strips allow passing vehicles to spot them in advance, reducing the risk of collisions.

Improving team collaboration efficiency: Workers can quickly identify each other's positions, avoiding collisions or misoperations.

(2) Providing Protection from Fire Sources

In petrochemical plants, refineries, or welding sites, fire sources and high temperatures are potential hazards. Flame-retardant properties can delay flame spread in a short time:

The fabric will not immediately burn or melt when exposed to fire, reducing the risk of burns.

Flame-retardant fabrics combined with high-visibility design ensure that workers can be quickly spotted by colleagues or rescue personnel, even in fire or smoke.

(3) Reducing the Severity of Accidents

Nighttime accidents often result in more severe injuries due to delayed rescue response. High-visibility flame-retardant fabrics can improve visibility and flame-retardant performance:

Providing early warning to drivers and machinery operators about the location of workers.

Delaying the time of injury upon contact with a fire source, providing valuable time for on-site emergency response.

3. Design and Functional Implementation of High-Visibility Flame-Retardant Fabrics

Color Design

Commonly uses eye-catching colors such as fluorescent orange and fluorescent yellow to ensure visibility in both daytime and low-light conditions.

Fluorescent colors absorb light during the day and work in conjunction with reflective strips at night.

Reflective Strip Placement

Reflective strips are usually arranged crisscross on the fabric, covering key positions such as shoulders, chest, waist, arms, and legs.

The width, spacing, and height of the reflective strips comply with international safety standards, such as ANSI/ISEA 107.

Application of Flame-Retardant Fibers

Using fabrics such as aramid, flame-retardant cotton, and flame-retardant polyester blends to provide long-lasting flame-retardant performance.

The fabric maintains its flame-retardant properties after multiple washes, ensuring long-term protection.

Breathability and Comfort

To prevent workers from overheating during nighttime operations, the fabric usually uses a breathable weave to ensure rapid sweat evaporation.

The multi-layer design combines flame-retardant and reflective functions while ensuring the clothing is lightweight and does not restrict movement.

4. Applications of High-Visibility Flame-Retardant Fabrics in Various Industries

Construction and Road Construction

Nighttime construction workers, signalmen, and machinery operators wear high-visibility flame-retardant workwear to reduce vehicle collision accidents.

Petrochemical and Energy Industries

In flammable environments such as refineries, natural gas stations, and chemical plants, workers wear flame-retardant high-visibility clothing to effectively prevent fire injuries.

Railway and Transportation Maintenance

Nighttime track inspection and maintenance personnel need to maintain visibility when trains approach to reduce accidents. Emergency Rescue

Firefighters, rescue workers, and night search and rescue teams wear flame-retardant, high-visibility clothing to ensure safety and facilitate mutual identification among team members.

High-visibility, flame-retardant fabrics play an irreplaceable role in ensuring safety during nighttime work. Workwear made from high-visibility, flame-retardant fabric not only effectively improves safety during nighttime operations but also enhances corporate safety management and protects employees' lives. As safety standards for nighttime operations continue to rise, high-visibility, flame-retardant fabrics will undoubtedly become indispensable protective equipment for nighttime work in various high-risk industries.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى