Embracing Innovative Technology for a Secure Future

Suppliers Of Flame Retardant Fabrics For Different Materials

-

-

-

-

-

-

-

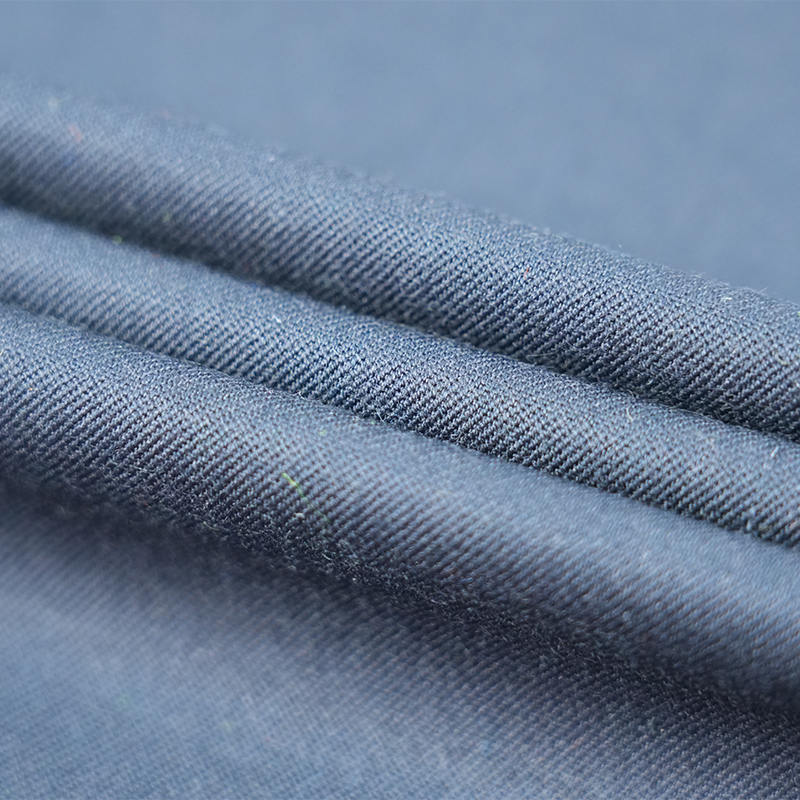

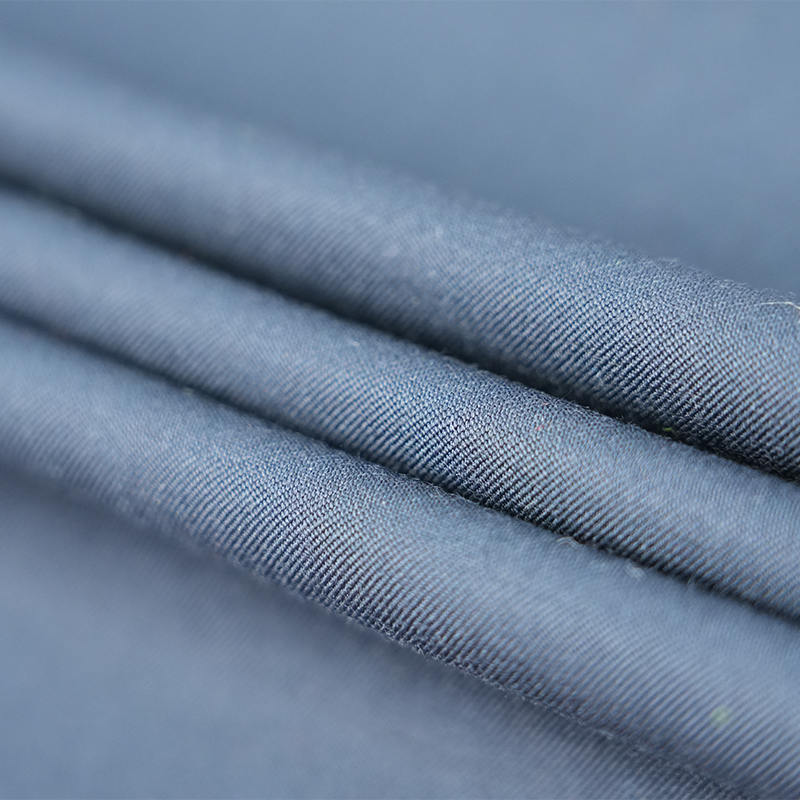

PFA-D12 Twill/Plain/Ripstop Electric Arc Protection FR fabric

-

-

-

SSS-A02 Herringbone with Ripstop Military and police special protective fabrics

-

SSS-AD1 Twill Military and police special protective fabrics

-

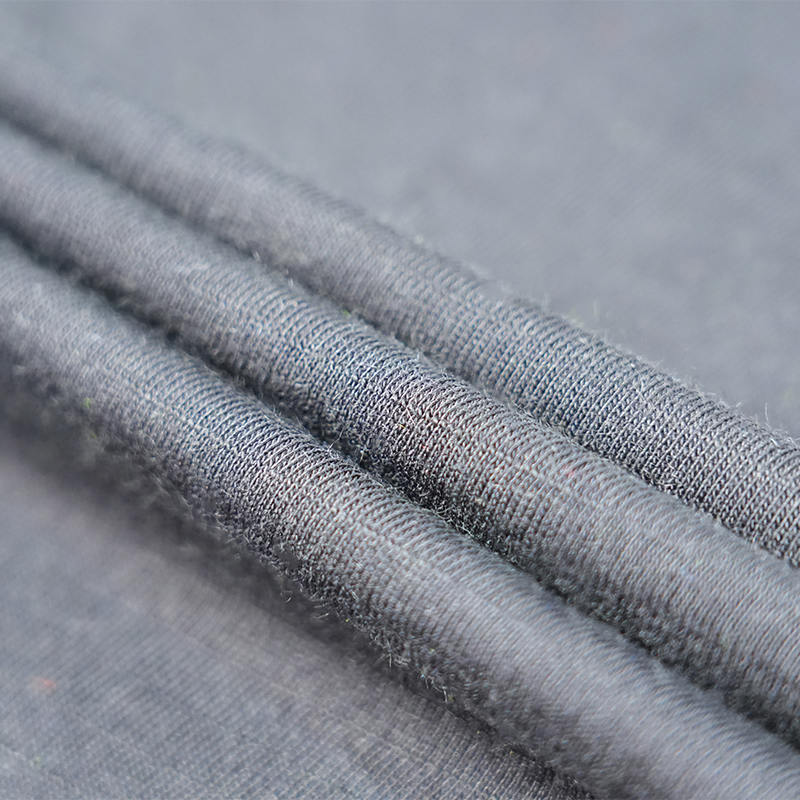

SSS-AD3 Twill Military and police special protective fabrics

-

-

-

FABRICS MANUFACTURER

-

0+

0+Enterprise establishment

-

0+

0+Employees

-

2026-01-30High Visibility Flame Retardant Fabric: Is It the Ultimate Safety Solution for Hazardous Workplaces?High visibility flame retardant fabric is widely used in industrial safety clothing, protective uniforms, and emergency response gear. By combining fi...

-

2026-01-23We are pleased to announce that our General Manager, Mr. An Biao, participated as a Council Member in the 2nd Session of the 5th Council of the China ...

-

2026-01-22When working in environments with potential fire hazards or low visibility, safety is paramount. One of the key ways to stay safe is by wearing the ri...

-

2026-01-19Our General Manager, An Biao, is representing the company at the 2025 Annual Meeting of the Haian City Industrial Economic Federation today.

The development of flame-retardant textiles is inseparable from the progress of materials science. Different fiber materials directly affect the flame retardant properties, comfort and application scenarios of textiles. From the flame retardant modification of natural fibers to the inherent flame retardant properties of synthetic fibers, modern flame retardant textiles have formed a diversified material system. Flame retardant textiles can be divided into two major systems according to the material: intrinsic flame retardant fibers and modified flame retardant fibers. Different materials have their own characteristics in flame retardant mechanism, protective performance and applicable scenarios.

3H Safety Technology Co Limited. is a professional custom flame retardant fabric manufacturer. The company is committed to the research and development and production of various flame retardant fabrics, and its products are widely used in mining, steel, mechanical processing and other industries.

Intrinsic flame retardant fiber: aramid IIIA fabric

- Material composition and characteristics

Aramid IIIA fabric is composed of 93% meta-aramid (Nomex), 5% para-aramid (Kevlar) and 2% antistatic fiber (P140).

Nomex fiber: glass transition temperature is as high as 275℃, limiting oxygen index (LOI) ≥28, forming a dense carbonized layer instead of molten droplets when burning

Kevlar fiber: tensile strength is 3 times that of steel wire, giving the fabric tear resistance

P140 fiber: surface resistance ≤10^9Ω, eliminating the risk of static sparks

- Performance advantages

Thermal stability: continuous use at 204℃ still maintains more than 90% strength

Anti-explosion performance: passed the GA10-2014 standard test, afterburning time ≤2 seconds

Structural optimization: twill weave (warp density 320 roots/10cm, weft density 280 roots/10cm) has the best flame retardant performance

- Typical applications

Petrochemical protective clothing: Sinopec standard workwear uses 220g/m² tear-resistant version

Outer fabric of firefighting combat clothing: cooperate with PTFE membrane to form a four-layer protection system

Composite flame retardant system: synergistic effect of aramid blended fabric

- Pre-oxidized silk aramid blended fabric

Material formula: pre-oxidized polyacrylonitrile fiber and aramid blended, balanced flame retardancy and mechanical properties

Key parameters: gram weight 270g/m², yarn count 16S×10S, suitable for 200-600℃ working conditions

Innovation: The trapezoidal polymer structure of pre-oxidized silk delays thermal decomposition, and the carbon residue rate is >60%

- Flame retardant viscose/acrylic chlorofiber aramid blended fabric

Three-component system: viscose (hygroscopic) + acrylic chlorofiber (flame retardant) + aramid (heat resistant)

Functional integration: meet the EN1149-5 antistatic standard and ISO15025 flame retardant standard at the same time

Modified flame retardant fiber: a breakthrough in acrylic technology

- Modified acrylic flame retardant mechanism

Chemical modification: 2,3-dibromopropyl acrylate is introduced through copolymerization, and the bromine content reaches 12%

Synergistic system: antimony trioxide/decabromodiphenyl ether composite flame retardant is used, and the LOI value is increased to 32

- Process innovation

Solution coloring technology: flame retardant is mixed with color paste before spinning to avoid strength loss after finishing

Low-temperature plasma treatment: phosphorus and nitrogen compounds are grafted on the fiber surface, and the LOI retention rate is >95% after 50 washings

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى