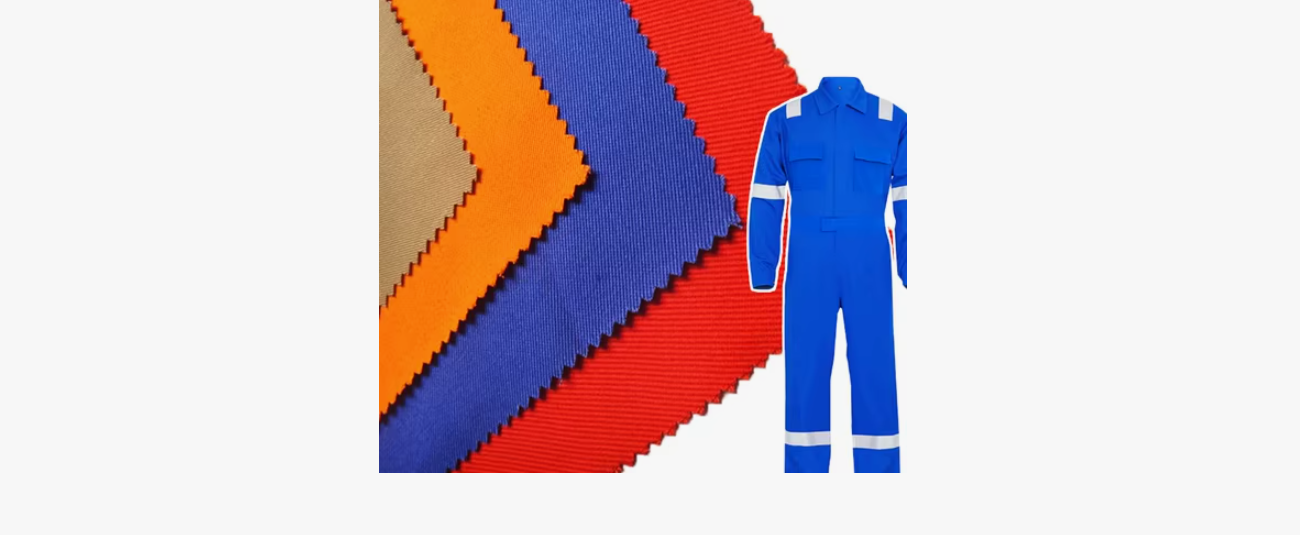

Flame retardant fabrics, as an important safety protection material, play a crucial role in various industries, especially in fire fighting, industrial production, power generation, and transportation. With the advancement of technology, the types and functions of flame retardant fabrics are becoming increasingly diverse. Therefore, choosing high-quality flame retardant fabrics is particularly important.

1. Understanding the Basic Characteristics of Flame Retardant Fabrics

Flame retardant fabrics primarily use special textile technologies and treatment processes to slow down or stop the spread of flames when exposed to a fire source. High-quality flame retardant fabrics should not only effectively prevent fire spread but also possess the following basic characteristics:

High temperature resistance: High-quality flame retardant fabrics can withstand high temperatures and effectively protect the wearer in a fire environment.

Non-melting or dripping: When the fabric is exposed to a fire source, good flame retardant fabrics will not melt or drip, avoiding secondary injury to the body.

Continuous protection: Flame retardant fabrics should provide continuous protection, and the flame retardant effect should be maintained even after multiple washes.

2. Choosing the Right Flame Retardant Fabric Based on Application

Different application scenarios have different requirements for flame retardant fabrics, so the needs of the actual use environment must be considered when making a selection. The following are several common types of high-quality flame retardant fabrics:

(1) High-Visibility Flame Retardant Fabric

In some work environments requiring high visibility, flame retardant fabrics must not only have fire protection properties but also ensure the wearer's visibility. For example, firefighters, construction workers, or traffic controllers often need to wear high-visibility clothing. In this case, high-visibility flame retardant fabric is the best choice. This type of fabric uses reflective materials, such as reflective strips and fluorescent colors, to ensure that it can be easily seen in low-light environments, thereby improving the wearer's safety.

Applicable scenarios: Firefighter uniforms, construction site uniforms, traffic safety clothing, etc.

Advantages: Provides efficient fire protection while enhancing visibility in nighttime or low-light environments.

(2) UL Certified Flame Retardant Fabric

Certification is a very important reference standard when choosing flame retardant fabrics. UL certified flame-retardant fabrics are products tested by Underwriters Laboratories (UL) in the United States and meet international certification standards. UL certification guarantees the flame-retardant performance of the fabric and its response speed to flames. This certification means that the fabric can effectively prevent the spread of fire in high-temperature environments and provide continuous protection during use.

Applicable scenarios: Firefighting suits, industrial protective clothing, power industry workwear, etc.

Advantages: Complies with international safety standards, ensuring high performance and reliability of the fabric.

(3) Arc Flash Protection Fabric

For workers in the power industry, especially power maintenance workers, the risk of arc flash is very high. Arc flash protection fabric is designed to prevent injuries caused by arc flash, possessing extremely high arc resistance and effectively preventing high temperatures and currents caused by arc flash from harming the wearer. This type of fabric is usually made of arc-resistant and flame-retardant materials, which can quickly isolate heat and protect the human body in the event of an arc flash.

Applicable scenarios: Power maintenance, chemical plants, electrical equipment maintenance, etc.

Advantages: Provides professional protection against arc flash, preventing high temperatures and currents from harming workers.

(4) Metal Splash Protection Fabric

In industries such as metal processing, welding, and casting, high-temperature metal splashes often occur. Metal splash protection fabric can effectively block splashing molten metal, preventing burns to the wearer's skin. This fabric usually uses special fibers that are resistant to high temperatures and metal corrosion, able to withstand splashes generated during welding and maintain protective effects for a long time.

Applicable scenarios: Welding operations, foundries, metallurgical industry, etc.

Advantages: Effectively prevents the hazards of high-temperature metal splashes and improves operational safety.

3. Other Factors to Consider When Choosing Flame-Retardant Fabrics

In addition to functionality and certification, the following aspects should also be considered when choosing high-quality flame-retardant fabrics:

(1) Durability and Washability

High-quality flame-retardant fabrics should have a long service life and be able to withstand multiple washes without losing their flame-retardant effect. Many low-quality flame-retardant fabrics may lose their effectiveness during washing, so choosing flame-retardant fabrics with good washability is crucial.

(2) Comfort

Although flame-retardant fabrics have fire-resistant properties, the comfort of the wearer should also be considered. The breathability, softness, and weight of the fabric all affect the wearer's comfort. Comfort is especially important in high-temperature or long-duration work environments.

(3) Compliance with Industry Standards and Regulations

Different countries and industries have different requirements for flame-retardant fabrics. Ensuring that the selected fabric complies with relevant industry standards and regulations is crucial. For example, in the United States, firefighters' uniforms typically need to comply with NFPA (National Fire Protection Association) standards, while in Europe, they may need to comply with EN standards. Therefore, when making a selection, ensure that the fabric meets local or industry safety standards.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى