In modern industrial production, construction, and high-risk industries such as energy and chemical engineering, the working environment is often accompanied by various potential hazards, such as flames, sparks, strong light, and vehicles passing by. To ensure personnel safety, more and more companies are beginning to emphasize personal protective equipment (PPE), and work clothes made of high visibility flame retardant fabric have become essential equipment in many industries. This type of fabric combines flame retardant properties with high visibility reflective effects, not only reducing injury in dangerous situations such as fires but also improving the visibility of workers in the environment, significantly reducing the accident rate.

1. Flame Retardant Protection: Protecting Lives in Critical Moments

Many jobs, such as electrical maintenance, welding, and petrochemical production, face risks such as sparks, deflagration, and high temperatures from short circuits. One of the core values of high-visibility flame-retardant fabrics is their use of special fibers or finishing techniques, enabling the fabric to automatically carbonize and quickly extinguish itself upon contact with fire, without producing molten droplets, thus effectively preventing the spread of fire.

Compared to ordinary textile fabrics that burn rapidly and produce molten droplets under high temperatures or open flames, flame-retardant fabrics can buy workers several seconds to tens of seconds to escape. In a crisis environment, this time is extremely valuable and can prevent severe burns or even death.

2. Improved Visibility, Reduced Accidents

Another undeniable advantage of high-visibility flame-retardant fabrics is their high reflectivity and highly saturated fluorescent colors. For outdoor work such as nighttime construction, low-light environments, rainy or foggy weather, or complex traffic conditions, ensuring workers are always visible is crucial.

Why is high visibility so important?

In highway construction, high-visibility workwear allows drivers to spot construction workers from a distance, reducing the risk of collisions.

In warehousing and logistics scenarios, forklifts and handling vehicles move frequently, and high-visibility fabrics can prevent collisions caused by blind spots.

In dimly lit environments such as mines and tunnels, high-visibility clothing can improve the efficiency of identification among colleagues, making collaboration safer and smoother.

Studies have shown that personnel wearing high-visibility safety clothing can reduce the rate of traffic accidents and industrial collisions by more than 30%.

3. Adaptable to various complex environments, comfortable and durable to wear

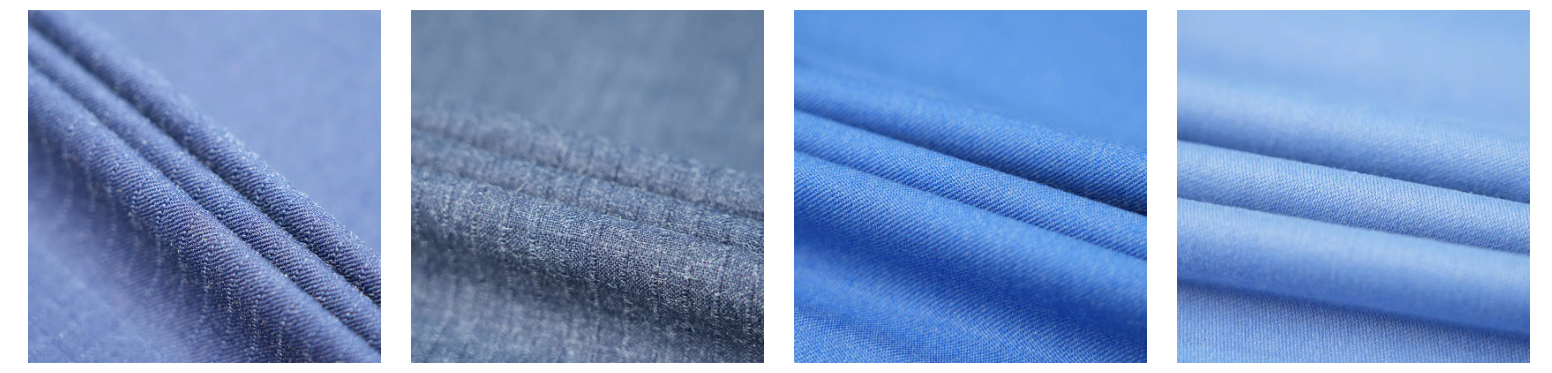

Modern high-visibility flame-retardant fabrics not only have strong safety performance but also take into account the comfort of workers wearing them for extended periods.

Excellent fabrics typically possess the following characteristics:

Lightweight design, reducing burden;

Excellent breathability, suitable for high-temperature outdoor environments;

High tear resistance, adaptable to frequent movements;

Excellent washability, maintaining flame-retardant and reflective effects even after multiple industrial washes.

This allows for its widespread application in industries such as power maintenance, fire rescue, oil field operations, traffic engineering, and construction.

The emergence of high-visibility flame-retardant fabrics provides workers with more reliable safety protection in high-risk environments. It can resist the threat of flames and improve visibility in low-visibility environments, preventing collisions and accidental injuries. Whether on construction sites, road construction, power maintenance, or chemical production, high-visibility flame-retardant fabrics play an irreplaceable protective role.

EN

EN 中文简体

中文简体 English

English русский

русский Español

Español Português

Português عربى

عربى